For the past few years Dr Matthew Dickinson, Senior Lecturer at The University of Central Lancashire (UCLan), has been involved in the ‘Primary Engineer MacRobert Medal’. Through the initiative, Matthew partnered with a local student to undertake research using the Ultimaker S5 that went on to be recognized at the UN COP26 conference.

A firm believer in encouraging young people to think outside the box, Matthew is a keen advocate of the award which celebrates the innovation of young people, connecting them to Universities to turn their ideas into a reality. When Krystyna Marshall, a 15-year old student from Sir John Thursby Community College in Burnley, entered the competition, with an idea to aid the mobility of children, Matthew knew that this idea was special.

Krystyna submitted her idea after seeing the struggles of her cousin living with Spinal Muscular Atrophy (SMA). Krystyna wanted to come up with an idea to provide support and give extra strength to her cousin’s back muscles and spine. Krystyna proposed a Spinal Muscular Atrophy (SMA) jacket based on the idea of an exoskeleton and her invention was just one of three to win gold. She is one of six people from across the UK to be recognized as a leading creative problem solver in engineering innovation, through the award.

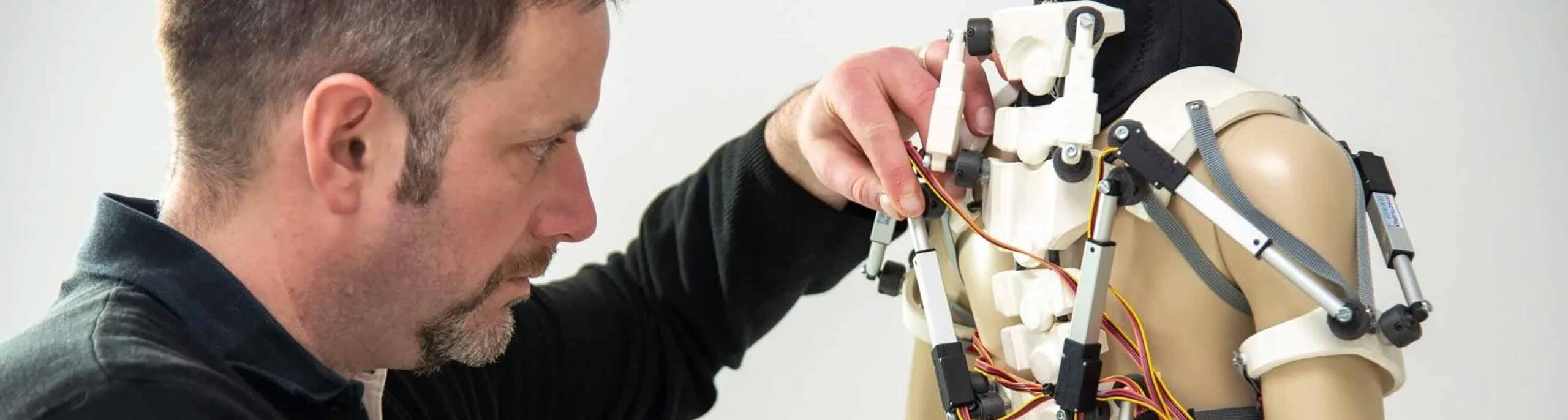

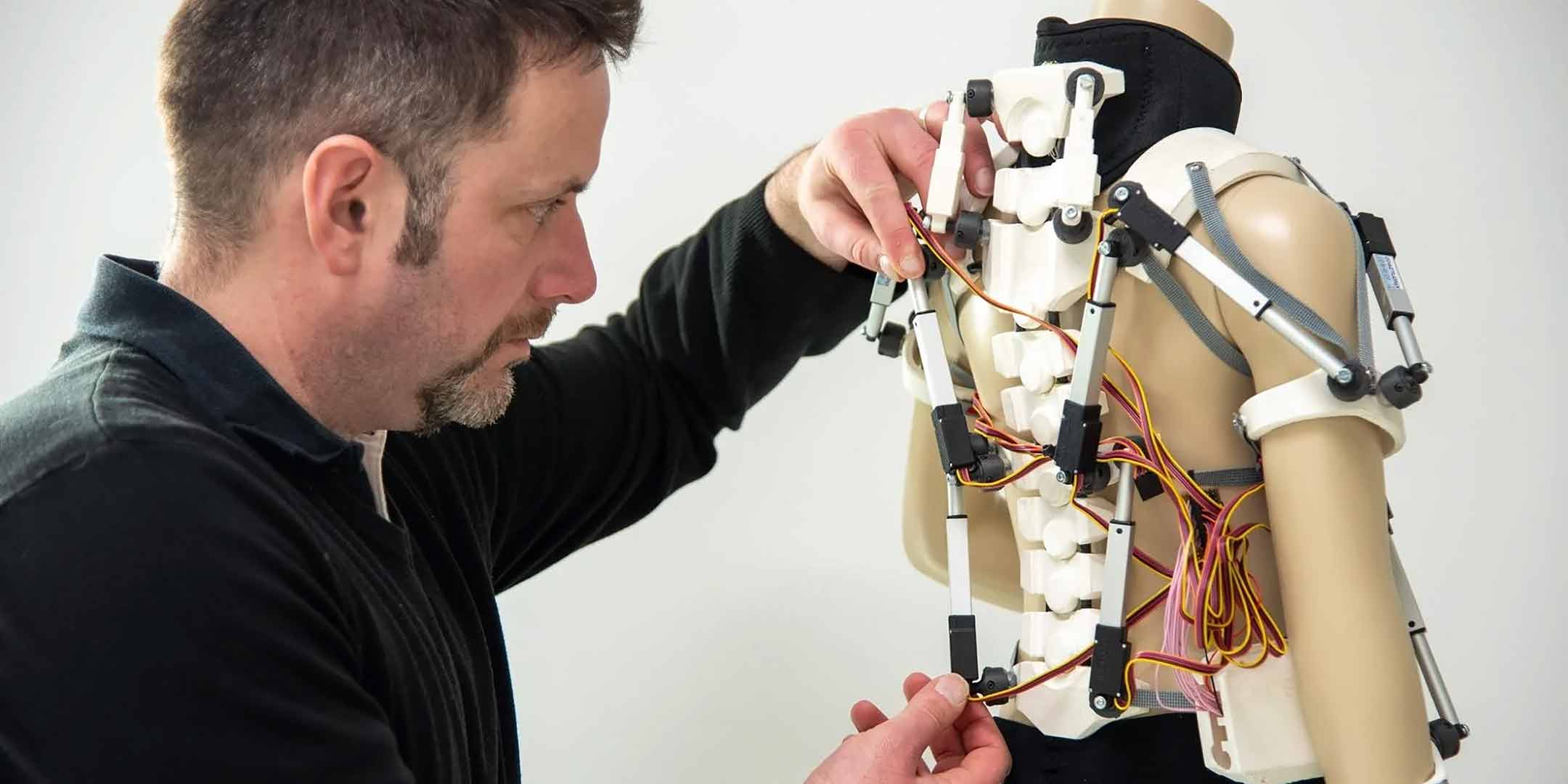

Krystyna with the exoskeleton model

The challenge

Fitting an SMA jacket to the human body creates multiple challenges. The initial idea was to manufacture the exoskeleton from aluminium.

However, when considering the growth rate of children and the resulting changes that would have to occur to the exoskeleton, costs became too high. Looking for alternative production methods, Matthew turned to 3D Printing. By producing low-cost 3D printed parts, the technology offered a high level of customization and reproducibility enabling the exo-skeleton jacket to become a solution for the prevention of injury and rehabilitation.

An exoskeleton is an assistive mechanical device worn externally to assist with movement or prevent injury

Using his Ultimaker 2+ printer, Matthew designed his first-generation exoskeleton and started prototyping using PLA. His results were both promising and an inspiration for further development but the geometries he was able to design and print became limited by the single extrusion print head of the Ultimaker 2+.

Moving forward: Prototyping the exoskeleton

To move past the limitations of the Ultimaker 2+, Matthew approached The CREATE Education Project.

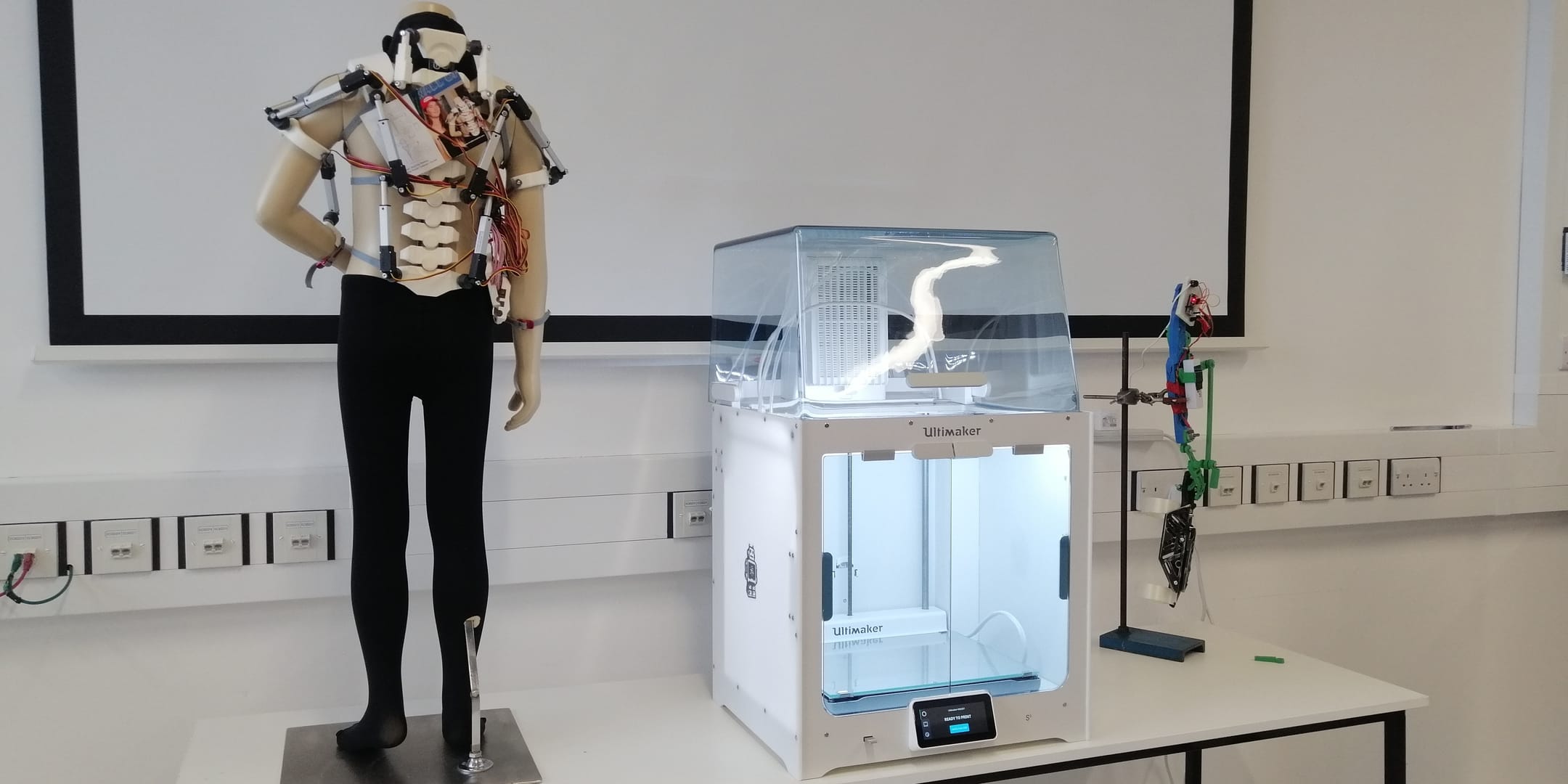

CREATE Education is a UK reseller that works solely with education organisations to support and provide access to 3D printing and technologies. As part of their offering, they introduced Matthew to the 3D printer loan scheme which was how he was able to step up to the Ultimaker S5.

The Ultimaker S5 offers dual extrusion and opened up the new material combinations and possibilities that helped propel the project forward.

The progression to the second generation prototype looked at 3D printing with multimaterials such as Nylon and TPU. With the Ultimaker S5, Matthew started experimenting with these materials using a PLA internal core and testing the external shell material in Nylon and TPU to find out which performed the best. Matthew discovered that they could produce components that would conform to a person yet provide rigidity because of the soft exterior and hardened interior.

Matthew is currently working on the third generation prototype and has manufactured a much sleeker design. He has also done the first test on a human body to support the lower limbs and the outcome has been very promising.

Taking advantage of Ultimaker’s ecosystem, Matthew optimized his 3D printing experience via the Ultimaker Digital Factory. Providing him with the ability to print remotely, create a digital library and monitor progress from any location. Matthew was able to work on the project in locations and at times that were convenient for him. The analytics available from Cura and the Digital Factory provide Matthew with material costs and printing times to enable him to plan the production of the exoskeleton and incorporate cost reductions into new iterations.

The results

Through the use of the Ultimaker S5, Krystyna’s idea to improve her cousin's life went from concept and design to prototyping and manufacturing in just six months. Matthew has stated that without the reliability and reproducibility of the Ultimaker S5 combined with Ultimaker Digital Factory software, he would not have been able to complete the project in such a short period of time.

Following the completion of the project, Krystyna, Matthew, and his team at UCLan were named the inaugural winners of the 2021 Primary Engineer MacRobert Medal at COP26.

Matthew is now working with medical students at UCLan to look at how bacteria can transfer to the exoskeleton from a human body. Professors from the university's biomechanics department are also working on this project to support it from a human ergonomics perspective. They are currently working on the third-generation prototype and have manufactured a much sleeker design. After completing the first test on a human body that supports the lower limbs, the outcome was very promising and they will soon reveal this design.

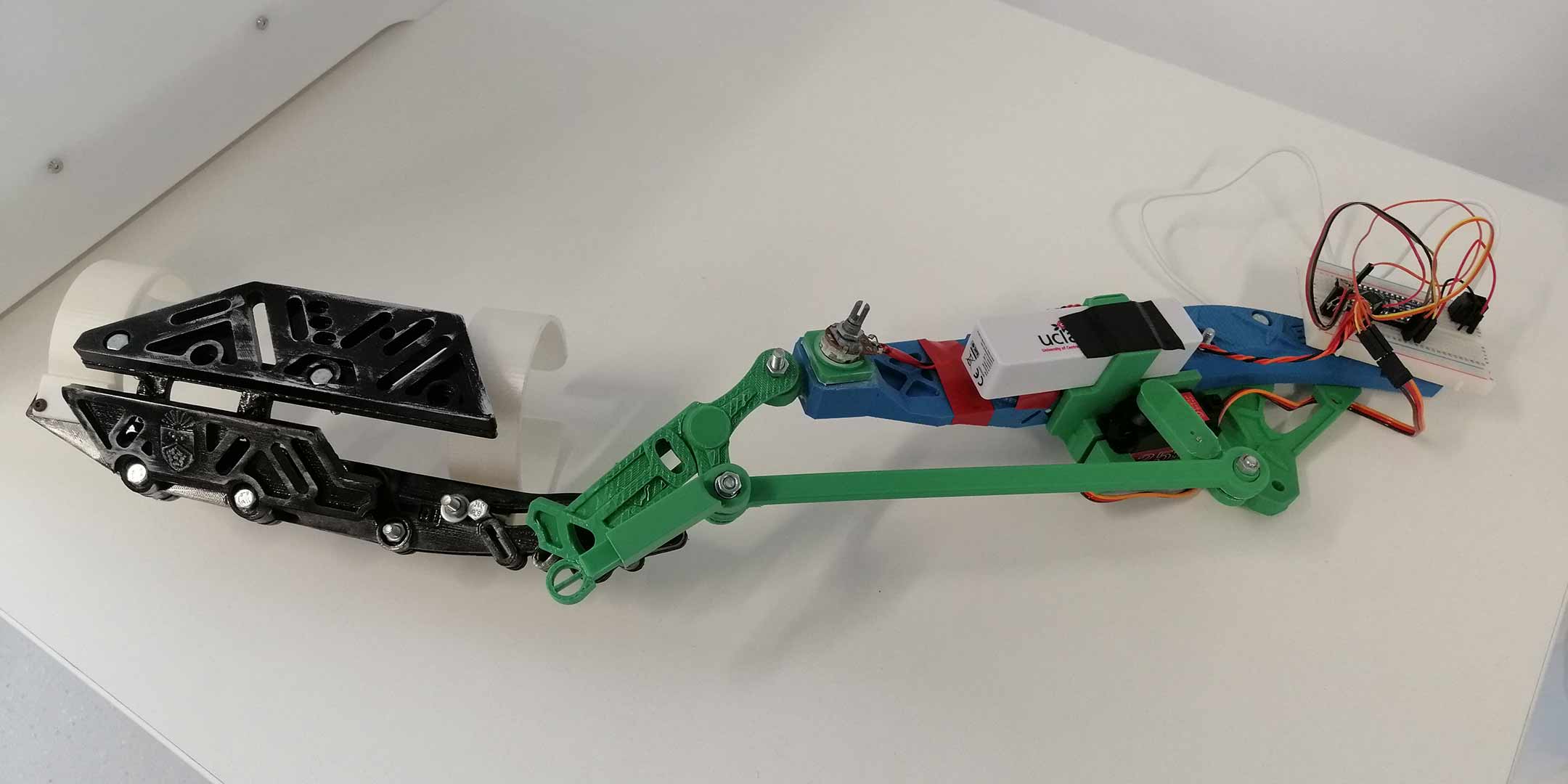

An assistive device prototype made with 3D printed parts

In addition to Matthew’s work within education, he has also become a chair member on the subcommittee for the American Society for Testing and Materials (ASTM). He is now advising the international exoskeleton standards to ensure exoskeletons are manufactured safely for human use. His involvement with the ASTM has enabled him to interface with international organizations, such as Ford, Boeing, NASA, and The UK Space Agency.

Through the combined efforts of Matthew and the ASTM, the technology behind exoskeletons is being introduced and taught to students in the UK and the USA. Their goal is to educate and inspire students about the human enhancing benefits of exoskeletons. To do this they have produced 5 short 10-minute episodes of interviews with industry professionals along with a design and build your own exoskeleton challenge. The challenge has been created by Matthew and this is now making introducing 3D printing into schools more accessible.

Matthew hopes to see the accessibility of exoskeletons soar in the not-so-distant future. His prediction is that 3D printing will be used by everyone to replace parts at home to help them become less reliant on waiting for parts from the manufacturer.

Discover more inspiring stories of how 3D printing can enable valuable innovation and unleash students' ideas in higher education.