Yesterday, Ultimaker had its second-ever Showcase event! The event was filmed in our Geldermalsen office in the Netherlands and it premiered on our YouTube channel where we had hundreds of viewers giving real-time feedback every step of the way!

Building on the precedent set by our October Showcase, we had a keynote from Ultimaker CEO Jürgen von Hollen as well as a number of illuminating presentations from industry experts. Both from inside of Ultimaker, and from the wider community.

To top everything off, we had an exciting announcement about the latest version of Ultimaker Cura! If you missed the event, you can still watch it in full below or keep reading to get a full recap.

Celebrating the achievements and the potential of 3D printing technology

The Showcase opened with a keynote speech from the CEO of Ultimaker, Jürgen von Hollen. In his speech, Jürgen shared his views on the strengths of FFF 3D printing and Ultimaker's 3D printing technology, while also introducing the speakers and topics for the rest of the showcase.

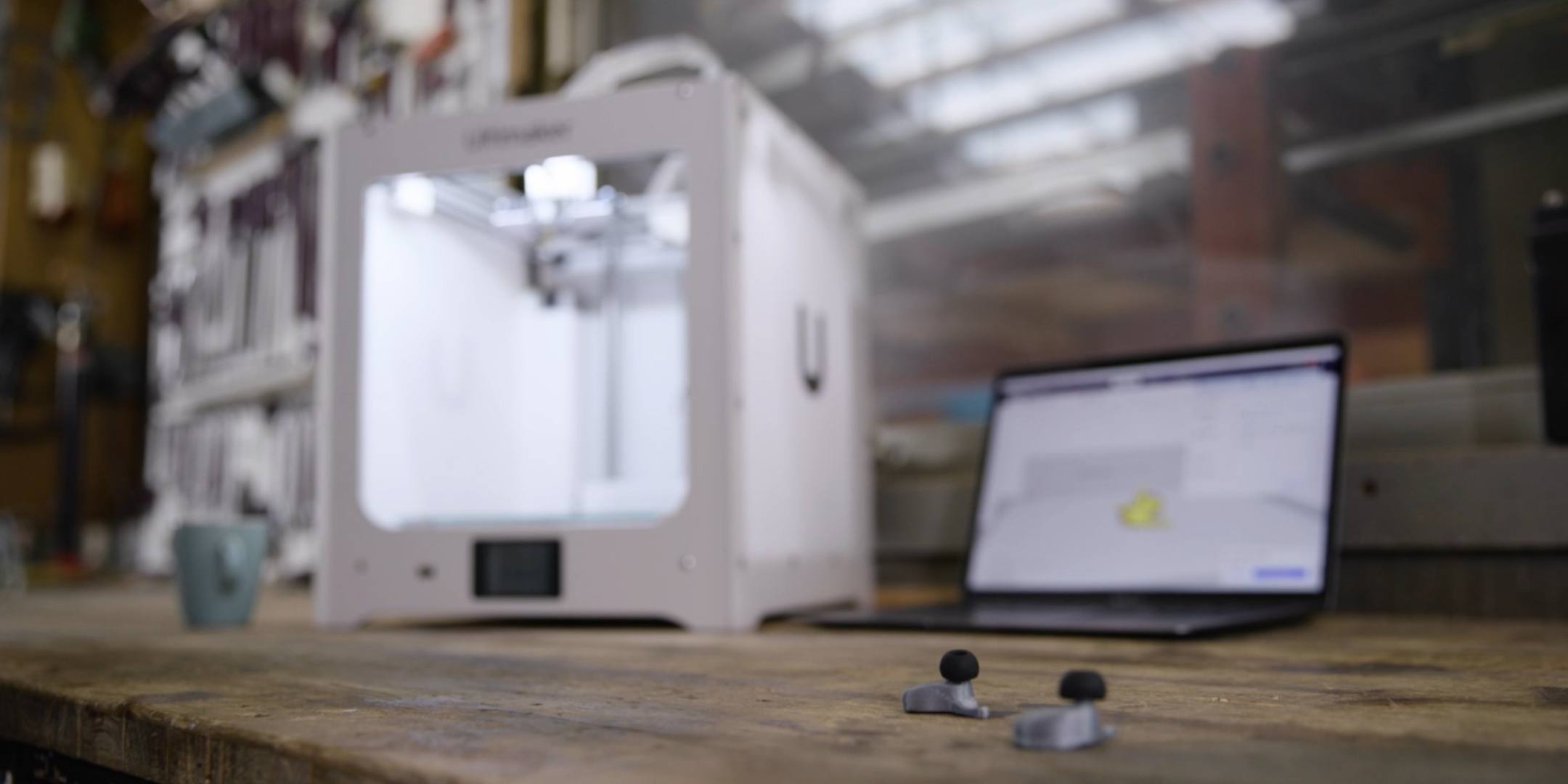

We're about making 3D printing a real possiblity for anyone who wants to turn an idea into a physical object in their home, garage, workshop, or factory.

During his talk, Jürgen took the time to celebrate Ultimaker Cura. He shared some of the many amazing (and in some cases unexpected) industrial applications that our users have found for 3D printed parts. Including:

Accelerated new-product introduction

Tools and fixtures to help keep factory workers safe,

Enhanced ergonomics for factory workstations,

Faster production line changeovers

Improved machine utilization

Improved factory productivity

He also talked about how important it is for Ultimaker to encourage access to 3D printing for everyone. Including inspirational use-cases like:

Socially inclusive organizations that make braille learning tools

Medics printing prosthetics and orthotics

Schools equipping the next generation of students with vital problem-solving and STEM skills

It's time to turn the table. From 'designing for 3D printing' to '3D printing for design' Solutions and applications focused. User focused.

As well as celebrating what 3D printing has enabled and accomplished until now. He also looked forward to how technology improvements can change how we approach designing for (and with) 3D printing. Improvements like those introduced in the latest version of Ultimaker Cura.

A breakthrough in 3D printing with Ultimaker Cura 5.0

During the Showcase, Ultimaker Cura version 5.0 was announced and viewers were told they could go and download the beta release immediately! In fact, users were slicing files with the beta and sharing the results in the YouTube live comments as the Showcase was still taking place!

Ultimaker Cura 5.0 is a huge leap forward in 3D printing technology with the introduction of a powerful new slicing engine that enables the printing of thin walls and fine details that would previously have been impossible. While also improving the strength of printed parts.

The latest beta release also comes with other improvements such as support for Apple M1 chips and faster print profiles for users of Ultimaker printers.

Throughout the presentation, 3D printing experts from both Ultimaker, and the wider 3D printing community, demonstrated how the improvements to Ultimaker Cura have enabled new possibilities in a wide range of applications.

For more details on all of these improvements, check out the full release notes for the Ultimaker Cura 5.0 beta.

Tom Dixon

The first of our guest speakers was the award-winning designer, Tom Dixon. Tom talked about how his London-based design studio uses Ultimaker printers for product development as well as small-batch production.

Some of the uses that make 3D printing an invaluable technology for Tom Dixon include the creation of:

There's something about being with a company that's got wide distribution and recognition that makes it easier for us to use the Ultimaker.

During his presentation, Tom also introduces a chess set that his studio designed specifically to show off some of the new features of Cura 5.0.

For any viewers who are avid chess players, it's possible to download the 3D models for it on the Ultimaker Cura download page and use them to print out your very own set!

Steve Cox

The Showcase also featured a talk by Engineer and 3D printing advocate Steve Cox. In his talk, Steve uses a part he designed to demonstrate the benefits of the new slicing engine in Ultimaker Cura 5.0.

Steve's design followed the requirements of an injection molded part with thin walls, clips, and, web features. All of these elements utilized the variable line width capabilities of the new slicing engine to create a part with fewer gaps and a more efficient tool path. And because Steve printed the part on an Ultimaker printer, he benefited from the improved print profiles in Ultimaker Cura 5.0, resulting in significantly faster print times.

So all of the things that we've seen in this presentation show how Cura 5 contributes to better quality printing, with higher effeciency. That for me, is a perfect combination.

As with Tom Dixon's model. You can download the part Steve designed in order to try it yourself!

Carlos Castillo

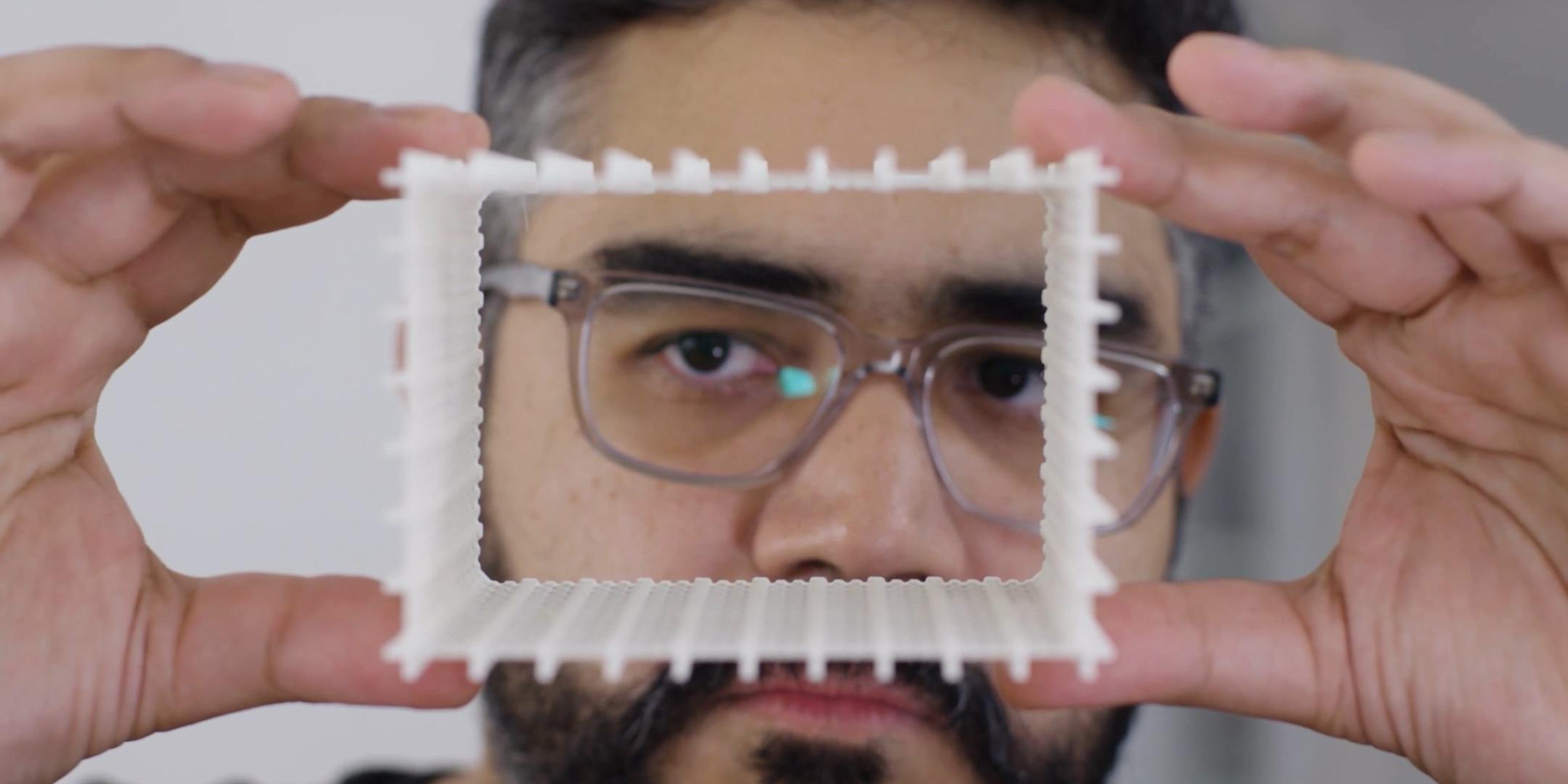

Next was the architectural designer, fabricator, and educator, Carlos Castillo.

Carlos is currently teaching at Parsons School of Design and he shared how 3D printing helps him and his students to bring their designs to life. During the Showcase, he also announced the ArchiToplogy Project. A collaboration with Ultimaker to produce a collection of 3D models of towers that can be downloaded, sliced, and printed by anyone. The work on this is ongoing and the full collection will be released shortly.

Models validate designer's ideas in a much more convincing way. One of the things that we're able to do now is to capture a lot of small details in even smaller scales. Cura 5.0 has allowed us to capture way more resolution.

Unlocking metal FFF

The final presentation in the Showcase was about metal FFF 3D printing. Ultimaker printers have previously been capable of printing metal materials but the new features of Ultimaker Cura 5.0 now make it easier than ever. Not only to get better prints, but also to improve the reliability of the debinding and sintering processes.

These features, as well as the wider benefits of metal FFF printing, were shared by Ultimaker experts Maritt Hoffmans and Andrea Gasperini, as well as Tobias Rödlmeier from BASF Forward AM.

BASF had early access to the metal FFF features of Ultimaker Cura 5.0 and they used it to validate the benefits by printing and processing some of the metal parts that are shown during the presentation. For anyone who wants to test metal printing for themselves, you can do so by using the new updated print profiles for the BASF Ultrafuse 17-4PH and the Ultrafuse 316-L metal filaments on the Ultimaker Marketplace.

After the showcase was finished, we held a live Q&A on Instagram. Follow us on Instagram to make sure you don’t miss any of our future Q&As.

We hope you enjoyed the showcase! Please share it with anyone else you think would enjoy it and we hope you'll join us at the next Ultimaker Showcase in the fall of 2022!