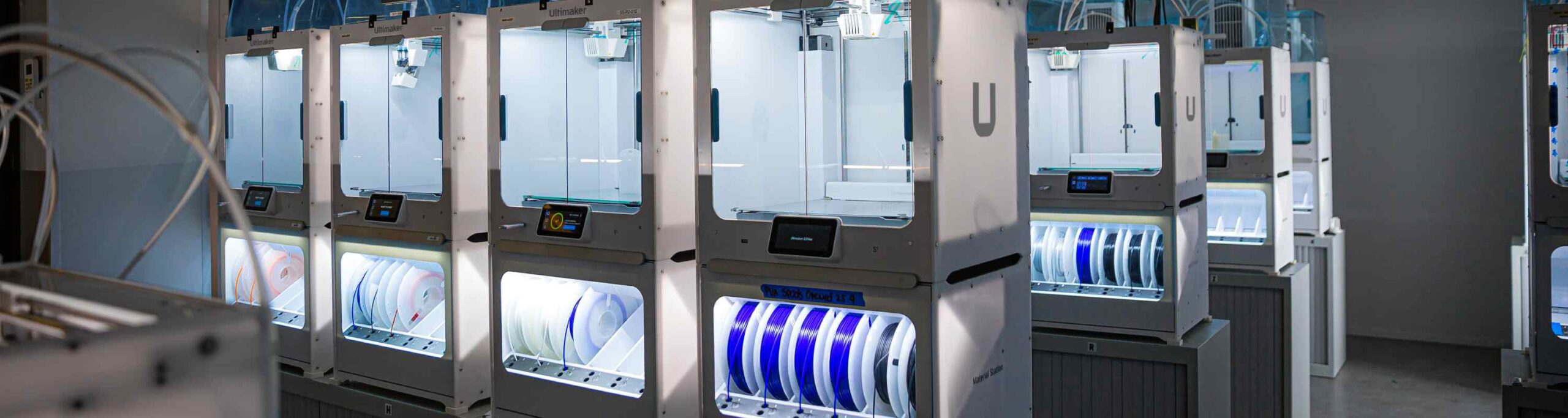

As 2021 comes to an end, so does Ultimaker’s 10th year. Now is the perfect time to look back at the highlights from the last 12 months and reflect on how Ultimaker was able to use a decade of innovation to reach new heights.

10 Years of 3D printing

We spent our 10-year anniversary not only planning for our future but also reflecting on our past. We took this opportunity to shine a spotlight on the wonderful employees who have been with us since the beginning and who helped get us where we are today. On our podcast, Talking Additive, we released a series of bonus episodes. In each one, host Matt Griffin interviewed a year one employee and together they paint a portrait of Ultimaker in its earliest years.

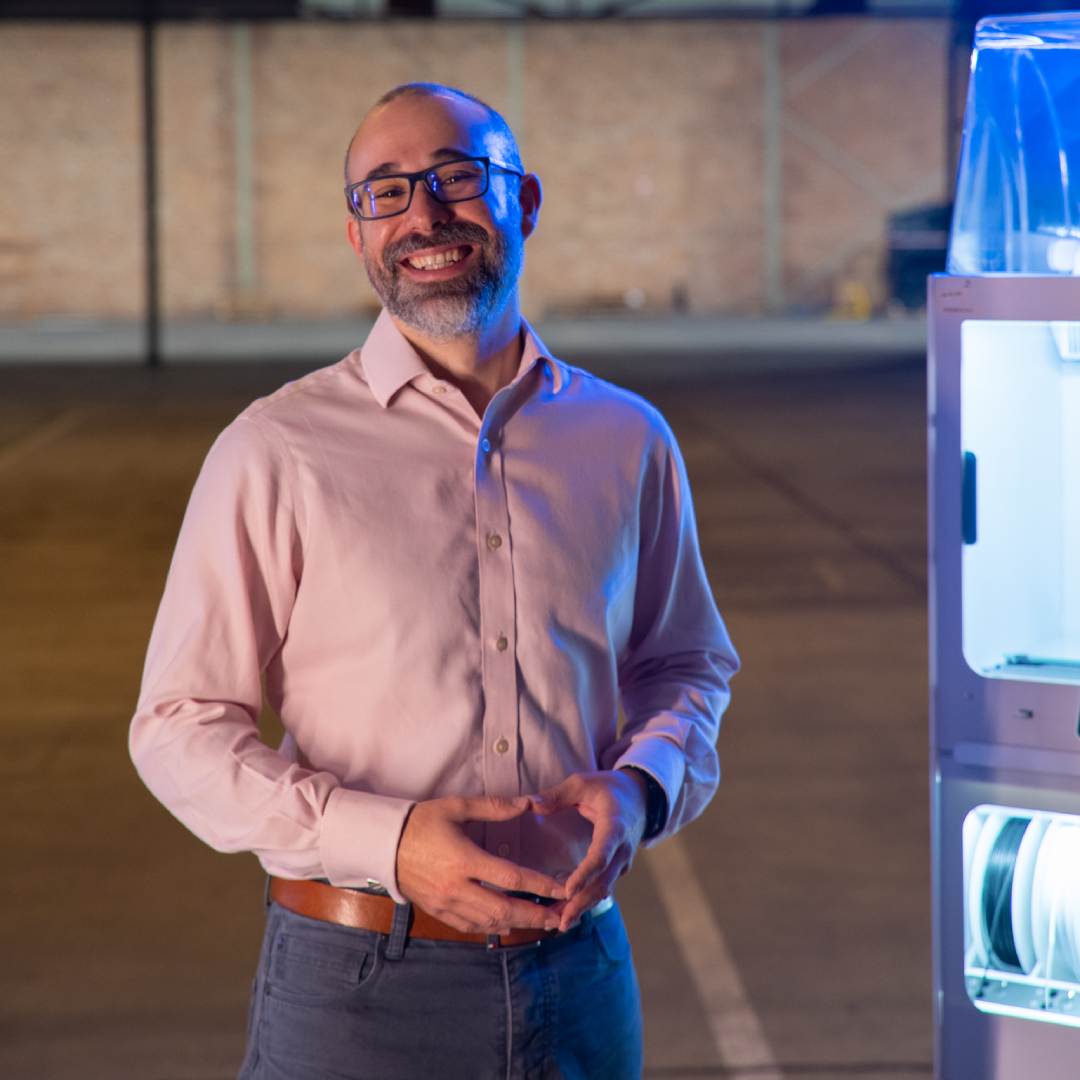

Talking Additive host Matt Griffin

He also interviewed Ultimaker co-founder Siert Wijnia which you can listen to on the feed or read about here.

Everyone who was interviewed had their own unique perspective, but the consensus seemed to be that the journey from assembling printers on a kitchen table to a global company with hundreds of employees has been a wild ride. And better yet, this is still just the beginning.

A year of software innovations

On the software side, Ultimaker delivered improvements, refinements, and new features this year on every front. On top of that, we also added two exciting new software subscription plans with Ultimaker Professional and Ultimaker Excellence.

Ultimaker Cura alone saw several new releases that included a whole host of improvements such as faster startup times and the addition of monotonic ordering which can help improve the quality of your top layers.

Without monotonic order settings enabled

With monotonic order settings enabled

The Ultimaker Digital Factory has added improved print filtering and monitoring tools, as well as a maintenance schedule and the ability to protect your print settings with a PIN code.

Firmware improvements have led to better error handling, a clearer UI that allows you to monitor the status of both your printer and your prints more easily, and the ability to pause and abort prints directly on the printer. Users are also now able to put their printer behind a firewall for added security and they can also set up a printer and import print profiles using USB.

Ultimaker Professional and Excellence are two new subscription tiers that offer a complete end-to-end production flow as well as top-tier support and access to new features such as the ability to print CAD files directly.

All these changes combined mean that your Ultimaker is more reliable and easier to use at the end of 2021 than it was at the start. And next year promises to be even better.

New leadership

As well as celebrating our history, we also made sure to keep looking forward. This year saw us gain a new CEO in Jürgen von Hollen and a new CTO in Miguel Calvo.

Ultimaker CEO Jürgen von Hollen

Ultimaker CTO Miguel Calvo

Both Jürgen and Miguel laid out their bold plans for the company during their speeches at the Ultimaker Transformation Summit in April and both also talked about the company’s promising future and some exciting developments during the recent Ultimaker Showcase.

New partners strengthen the Ultimaker ecosystem

Just as important as our printers, is the ecosystem we’ve built around them. We’re happy to say that there have been lots of amazing new partners joining that ecosystem in the last year. Each partner has been able to contribute in their own way by offering a range of benefits such as support, better integrations, and even custom software solutions for our users. This year we’ve partnered with Castor, Siemens, Autodesk, and others to make the Ultimaker ecosystem better than ever.

We also worked directly with one of our existing material partners LEHVOSS Group to develop our first Ultimaker certified material, the LEHVOSS Group LUVOCOM 3F PAHT® 9825 NT. This is a custom Polyamide-based material with extremely high-temperature resistance and a high level of dimensional accuracy. As an Ultimaker certified material, it’s made to work perfectly with Ultimaker printers and benefits from features that were previously only available on first-party materials, such as custom print profiles. This is just the first of many certified materials we hope to help bring to our users in the years to come.

LEHVOSS Group's filament is the first of many Ultimaker certified materials

Hardware and materials

Aside from all the software and ecosystem improvements we’ve made. We also released new physical products you can get your hands on.

Firstly, we released the new 0.4 mm print core CC as well as an improved version of our previously available 0.6 mm CC. Both print cores have hardened steel nozzles with a Titanium Nitrite coating that makes them extra wear-resistant and able to print with abrasive and fiber-filled materials more reliably than ever.

We also released our own Ultimaker PETG which has a great balance of printability and functionality and is available in a variety of colors (as well as transparent and fluorescent). That means you can now print one of the most useful materials around with the peace of mind of knowing that it’s been designed to work perfectly with Ultimaker printers.

Exciting things to come!

While it’s fun to take some time to reflect on all the amazing things that have happened in the last year (and the last 10 years) it’s important to remember that we have lots more exciting things to come.

At our Ultimaker Showcase, we announced our PVA Removal Station which is being released in the first half of next year and will make the process of removing PVA support material up to 4 times faster.

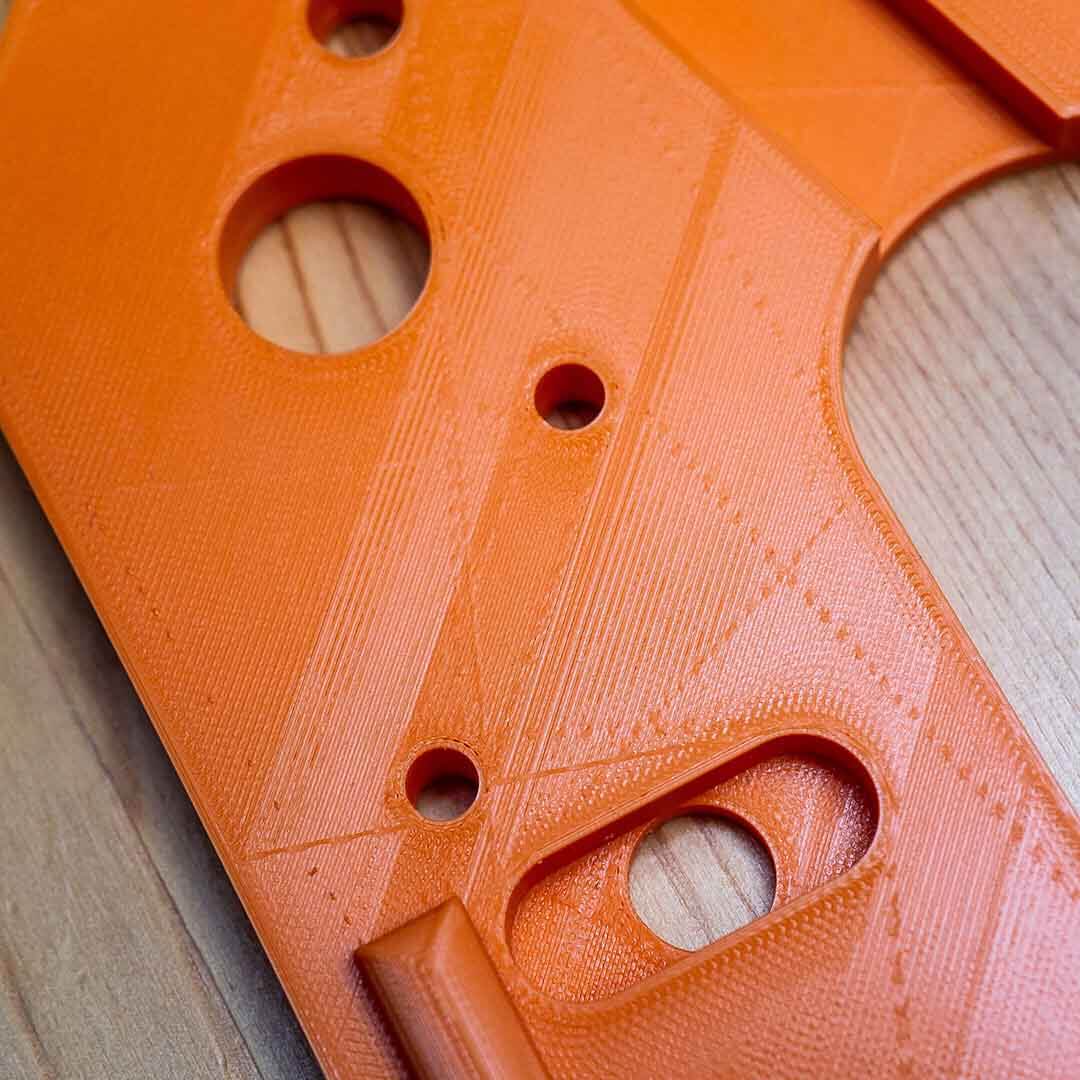

We also expect a full stable release of the Ultimaker Cura Arachne engine next year. Arachne is a major change to the Ultimaker Cura slicing algorithm that allows for faster prints, stronger parts, and better printing of thin and intricate shapes. Better yet, it’s in beta now so you can already try it for yourself.

If you want to keep up with these exciting developments, and the many more to come, sign up for our newsletter so you can be one of the first to hear about them.