Old Dominion University uses Ultimaker 3D printers to deliver a new level of innovation and confidence for engineering students.

When engineering student Aric Veatch started helping out at the university’s new Engineering Makerspace and Invention Center (EMIC) in 2017, he was intrigued by the center’s Ultimaker 3D printers. “The long-term and operational data on the Ultimaker systems was far better than the nearest competitor, and the purchase cost was exceptional,” said Veatch. “Seeing if they lived up to the expectations set was the first thing on my mind.”

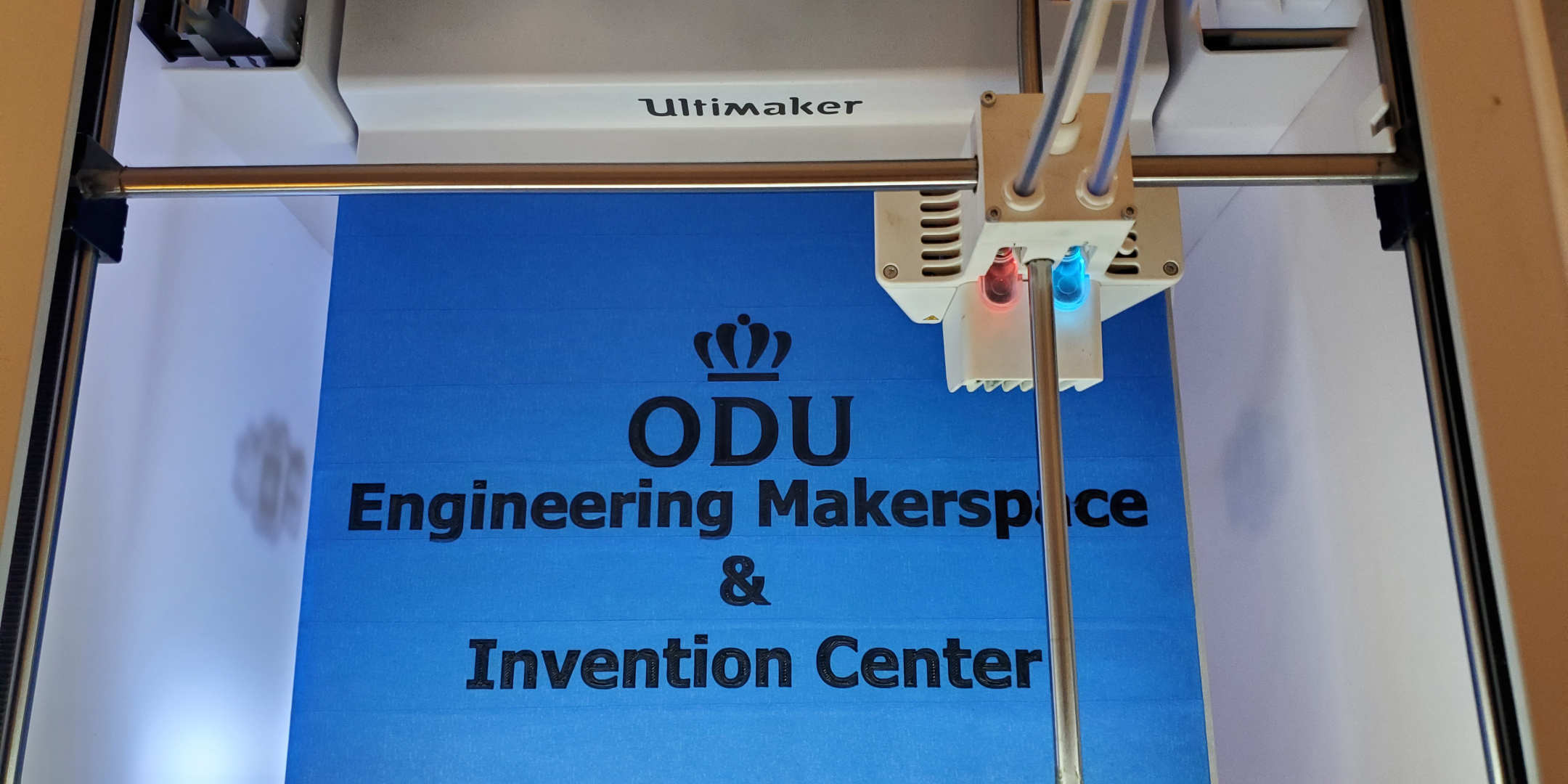

In 2017, the dean of the Frank Batten College of Engineering & Technology at Old Dominion University in Norfolk, Virginia, had a vision to create an advanced makerspace that was owned and operated by students. As a result, the $1.5m Engineering Makerspace and Invention Center was founded, providing a resource for any student to try out new design ideas. The center offers a range of resources including CAD design and testing, electronics production, metal, wood, and composite machining, welding, finishing, and 3D printing.

“The center was built with the mission to produce engineers as critical thinkers, leaders, and problem solvers,” said Rafael E. Landaeta, Ph.D, associate Engineering Makerspace and Invention dean at the Frank Batten College of Engineering & Technology. “Our aim is to give student engineers the edge they need with employable skills for the market.”

Inside the ODU Engineering Makerspace and Invention Center

The Ultimaker 3D printer in operation

With the 3D printers, the intent was for students to have access to rapid prototyping tools, so they could create finished parts at the attached workspace area that has an array of traditional manufacturing tools. According to Veatch, however, the quality of the 3D printers and materials was high enough that most designs are not just being prototyped in the maker-space but produced as 3D printed end-use parts.

“We wanted to have a variety of different printers, but we paid close attention to the reputation of the manufacturer, the long-standing reliability of its service, and how easy to use its products are,” said Dr. Orlando Ayala, the director of EMIC. “Undeniably, Ultimaker did fit all the criteria.”

An Evolution in learning

The EMIC was designed to enable ideation and prototyping of these ideas, and there were a lot of students keen to take the opportunity. The two Ultimaker S3 and one S5 desktop 3D printers quickly became part of the engineering department’s syllabus. Veatch was appointed as the student operations manager as part of his graduate studies to operate the 3D printers as well as other engineering systems in the EMIC.

“The usage on the 3D printers ramped up quickly,” he said. “By November 2019, all the printers were in constant use and we had ordered another Ultimaker S3 to help with demand.”

The Ultimaker systems use fused filament fabrication (FFF) technology and are compact enough to fit on a desktop while delivering generous build sizes: The S3 offers a build size of up to 230 x 190 x 200 mm with dual material fusion, and the S5 can build up to 330 x 240 x 300 mm—both with layer thicknesses as small as 20 microns.

These specifications make it possible for the students to think big. The ideas and parts being created advanced quickly to the point where students were not just designing and producing parts for coursework, but were experimenting with and producing parts for other engineering challenges.

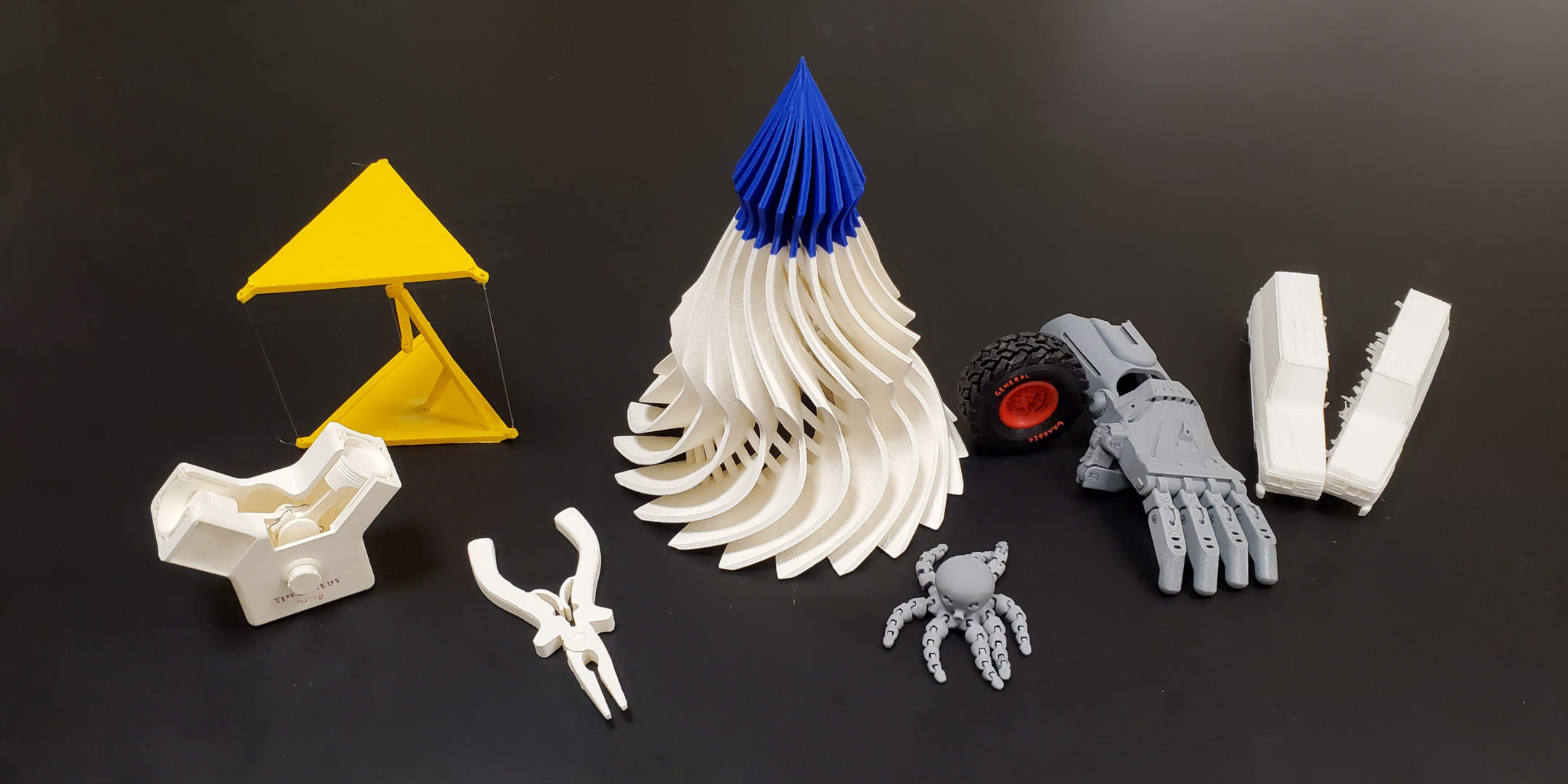

Parts produced range from fidget spinners and fictional character masks to difficult-to-source parts for vehicles.

Test prints including a 4-stroke engine printed in white PLA, tensegrity table (yellow ABS), spiral Christmas tree (white and blue ABS, and an articulating hand (gray PLA)

Ultimaker also offers over 150 materials for its customers, and the engineering students quickly focused in on their favorites.

“The materials delivered by Ultimaker, especially TPU and PLA, make it appropriate to deliver end-use parts for certain engineering scenarios, such as bushings for a gear shift,” said Veatch. “It has been amazing to watch the evolution in what students believe is possible with 3D printing, and they quickly went from basic to very advanced projects.”

Ultimately, he says, 3D printing is enabling a generation of better engineers who think in the 3D space and are evolving at a faster rate.

“The experience of the makerspace with Ultimaker has meant that our student engineers have completely exceeded expectations of what could be achieved,” said Dr. Landaeta. “We have been completely blown away by the students’ work.”

Ease of operation

Veatch quoted the following benefits with production using the Ultimaker platforms: ease of use, ease of maintenance, high-quality materials, comprehensive software, and low cost of ownership.

“Once I had the 3D printer out of the box, it took half an hour to be up and running,” said Veatch. “Since you can switch around the print cores easily, it makes it easy to keep a printer going while you repair another.”

He also cites the high-quality materials supplied with the Ultimaker, including the PLA and TPU materials, but also the freedom to source and use filament from other sources without limitations.

All Ultimaker systems come supplied with the Cura software—a free, high-performing 3D print preparation software solution. It operates with all major CAD file formats and is open source, enabling availability to anyone.

“The Cura software is just great for the print preparation,” he said. “You can also do changes to the print data on the fly during a print, which is great for fixing a problem without having to totally restart the build.”

Engineering in a virtual class

The stay-at-home orders for students and faculty at educational institutions across the country have disrupted many classes. However, both Dr. Landaeta and Dr. Ayala have taken it in stride as a very fast, and unexpected, pilot study into how engineering studies can be conducted in a virtual setting.

“Virtual engineering processes have been successfully implemented across commercial organizations,” said Dr. Landaeta. “However, this has required a good investment in time and technologies. These last three months just accelerated what we believed was going to take years to become normal in engineering.”

Dr. Landaeta points out that a big portion of engineering requires hands-on work for the production of parts and products, which means that while the design work can be easily conducted in a virtual space, the prototyping, testing, production, and maintenance stages still need an extended team in a physical space. However, 3D printing is helping overcome some of these limitations.

For the upcoming Summer Bridge program, which introduces graduating high school students to the university’s engineering program, 3D printed parts became a cost-effective option to continue the class in a virtual environment. The team has cost-effectively 3D printed and delivered entire transmission models to the students so they can continue the program in a virtual setting.

“Low-fidelity 3D printing technologies are affordable enough to have them at home,” said Landaeta. “Nothing replaces touching and holding a prototype, moving it, placing it in perspective against other objects, and feeling its surface.”

To help prove the theory, the 3D printers were taken to Veatch’s home when the lockdown started, where the small desktop footprint remained easy to handle.

“Moving the 3D printers around is fast and easy,” said Veatch. “It is less easy to move the bigger traditional manufacturing machines plus you have to have space for them. The Ultimakers are clean and small enough to be used in my house.”

3D design data is sent to Veatch across the university’s intranet, the parts are printed, and then shipped back to the student for analysis and testing.

“The Batten College of Engineering & Technology plans to support the education of this new engineering normal. We now need to teach our students how to be successful engineers in virtual engineering environments,” said Dr. Landaeta. “3D printing technologies are at the forefront of these efforts, allowing students to prototype from campus or from home.”

The EMIC is now planning to further expand the amount of 3D printers available, hoping to operate between 12 to 20 in the future. They are also looking to expand the operation of the 3D printing with the Ultimaker Digital Factory software to help manage the 3D printer fleet as it grows.

“We are very happy with the Ultimaker 3D printers. The students have been able to work on amazing projects with ease,” said Dr Ayala. “We are planning on buying more Ultimaker 3D printers in the future.”