FFF 3D printing, or fused filament fabrication, is an additive manufacturing (AM) process in which thermoplastic material is pushed through a heated nozzle to create objects layer by layer.

What Is FFF 3D Printing?

While it has its origins as a proprietary manufacturing technology from the 1980s, desktop FFF really took off just over 10 years ago when patents expired and projects like the open-source RepRap initiative led to greater innovation and affordability.

Today, FFF technology is typically a lower-cost solution compared to other 3D printing processes, both in terms of initial investment and running costs. It’s also renowned for being easy to understand and use – making it ideal for busy engineers and elementary school kids alike.

But it has proven so reliable, accurate, and capable of producing robust parts over the years that most of the world’s leading manufacturing, design, and education organizations now use it to drive innovation.

The FFF 3D printing process

FFF 3D printing uses

Let’s look more closely at the applications of FFF 3D printing:

Manufacturing. With faster lead times than outsourcing and a wide range of engineering materials, FFF 3D printing is used widely in manufacturing industries. 3D printers deliver rapid tooling and replacement parts to maintain maximum uptime and productivity on the production line. And they are used to flexibly create end-use parts, such as bespoke quality gauges or small batch first runs, to speed up time to market of a product

Prototyping. Low-cost materials and short print times make FFF 3D printing ideal for the iterative design process. 3D printed prototypes can be used to visualise concepts or functionally test technical parts

Education. Affordable and easy-to-use FFF hardware enables a variety of education applications – from engaging younger students with STEAM basics to providing production labs for college and university students to work on engineering projects and develop skills for the modern workplace

Ford saved roughly $1,000 per tool by developing 3D printed manufacturing aids using Ultimaker printers

Learn more about the range of 3D printing applications and how experienced AM engineers identify them in this episode of the Talking Additive podcast.

FFF materials

Plastic polymers are the most used materials for FFF technology, of which there are many for countless uses.

Composites that combine a polymer with fibers of carbon, metal, glass, or other materials are also widely used for various structural benefits, although these cannot be printed reliably on all FFF 3D printers. Technically it is also possible to print food and biological pastes using 3D printing technology, although this is typically reserved for experimental or research applications.

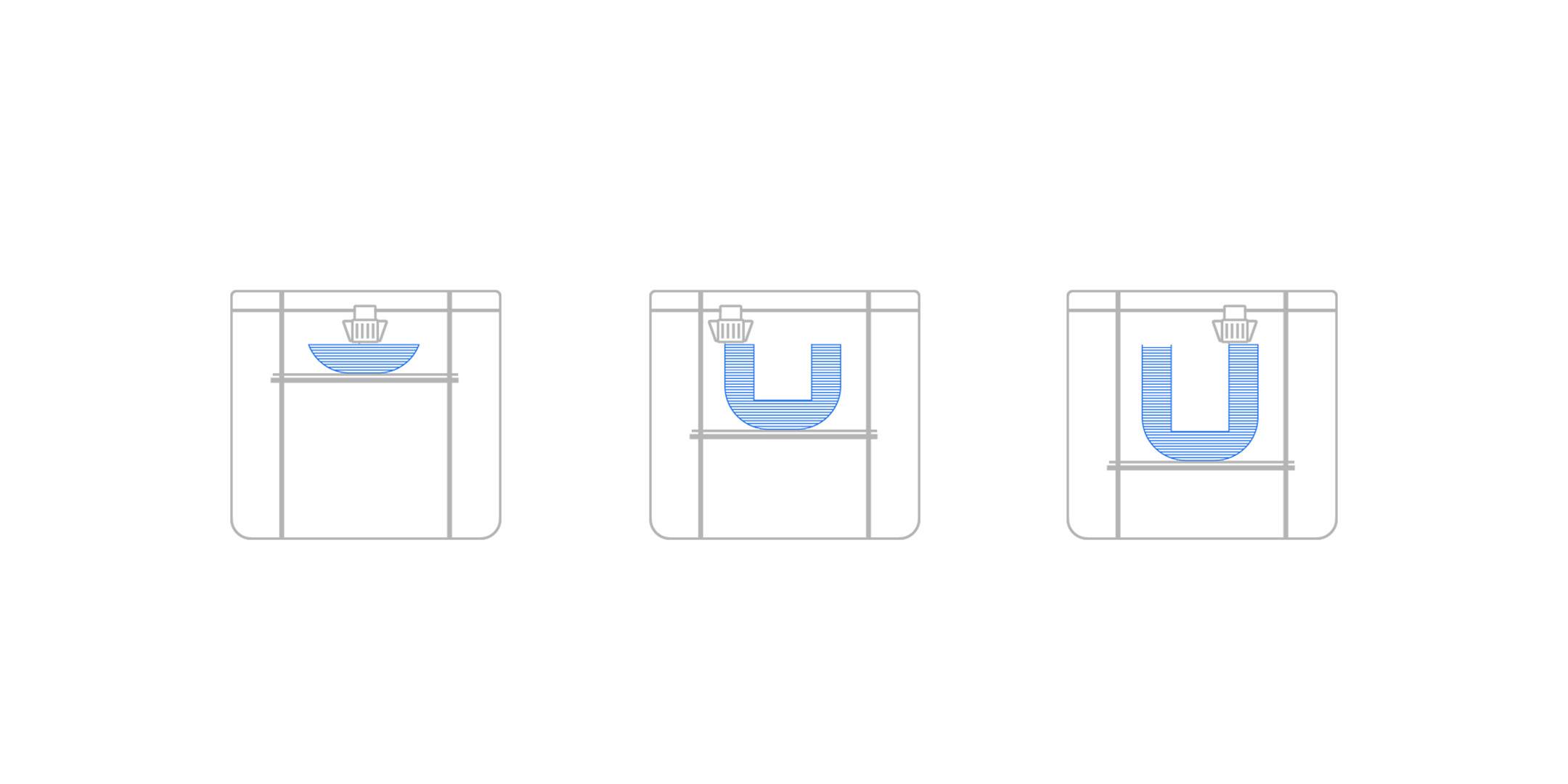

Another important category of material for FFF printers is known as “support” material. This is needed when the orientation or shape of a part makes it impossible to print from bottom to top – for example, a part with a large overhang. Support materials are designed to be easy to remove.

Material for FFF 3D printers is typically sold as spools of filament, each containing from 250 g to 1 kg of material.

Some 3D printers can print parts with multiple materials or colors

Loading filament on an Ultimaker S5 Pro Bundle printer

If you’re thinking of buying a 3D printer, always check the compatible materials.

For some, you may be limited to using two or three materials. Other printers may claim to work with any material, but soon develop technical issues from wearing caused by printing abrasive composite materials. And some FFF 3D printers are limited to using the manufacturer’s proprietary materials only, while others offer an open filament system (like Ultimaker) compatible with third-party products.

Some of the most common FFF 3D printing polymers are PLA (polylactic acid), which is often used as a “beginners” material due to its ease of use, and ABS (acrylonitrile butadiene styrene), which offers some superior mechanical properties and heat resistance.

But with thousands of filaments on the market, it’s worth diving a little deeper into their properties to get an understanding of how many applications are possible with a high-quality FFF 3D printer.

| Material | Properties |

|---|

| PLA (polylactic acid) | Excellent surface quality and detail. Mechanical and heat properties not suitable for some applications |

| ABS (acrylonitrile butadiene styrene) | Strong, ductile material with wear resistance and heat tolerance |

| Nylon (polyamide) | Strong yet flexible, with good chemical, impact, and abrasion resistance |

| PETG (polyethylene terephthalate glycol-modified) | Good toughness and wear resistance, with chemical resistance against many industrial fluids. |

| CPE (copolyester) | Durable and flexible with a glossy finish and good impact and heat resistance |

| PC (polycarbonate) | Strong and tough material with heat resistance up to 110 °C |

| TPU (thermoplastic polyurethane) | Flexible material with rubber-like properties. Provides high impact and wear resistance |

| PP (polypropylene) | Durable, tough, and fatigue resistant. Retains shape after torsion, bending, or flexing |

| PVA (polyvinyl alcohol) | Water-soluble material used to create supports for overhangs and cavities |

The table above covers the main polymers you can print on a professional 3D printer. Want to find the right composite material for your 3D printing applications? Watch our webinar on composites for 3D printing.

FFF 3D printers

Although FFF 3D printers are all built on the same process, their capabilities differ a lot.

One of the biggest differences can be in material compatibility (see the section above), with the hardware being especially important in defining what sort of composites can be printed.

Size is another key differentiator of FFF 3D printers. The printable space (which limits the size of a single print or batch) is called the build volume or build envelope. This can vary considerably – from 10 cm (3.9 inches) of printable space in the X, Y, and Z dimensions, up to around 1 meter (39 inches) in one or more of these dimensions in the largest units. Note that a stiff, stable build platform aids the FFF process – so large format printers generally mean a trade-off in quality.

An example of the different sizes and configurations possible with FFF 3D printers

The different features of a FFF printer are too many to highlight in an introduction, so here are definitions of a few of the most important:

Build plate or platform. The surface onto which the material is extruded and then cools to form the printed part. It is typically made of glass or metal. A professional standard 3D printer should offer a heated build plate, which enables use of more materials

Nozzle. The nozzle extrudes the molten material. It is housed in the print head and positioned via a gantry operated by stepper motors. The number of nozzles a printer has will determine how many materials can be combined in one print – typically one or two (known as single or double extrusion)

Feeder. The mechanism that feeds filament from the spool to the printer

Display. The interface through which the printer is controlled

Connectivity. Many 3D printers offer local network or cloud connectivity for remote operation

Environment control. While some FFF 3D printers are little more than open platforms, enclosing the build chamber and adding environment control (such as the Ultimaker S5 Pro Bundle) offer both print quality and safety benefits

Material handling. Filament is loaded and stored in many different ways on FFF 3D printers. This can range from basic printers, where the spool must sit separately, to professional solutions that offer front-loading and automatically switch spools when a filament finishes

You can compare the features of Ultimaker 3D printers here.

Finally, it’s important to mention software. Unless you have all the 3D prints you will ever need sitting on a USB stick, you will not be able to do much without the right software.

In 3D printing, software plays two important roles. First, a “slicing” program like Ultimaker Cura is essential for preparing a design file (such as an STL) for print. Load the file into this software, choose your desired print settings (such as fast or extra detail), and it will “slice” it into layers then create a file format the printer understands.

Preparing a model to be 3D printed using Ultimaker Cura software

This print job can then be transferred to the printer manually (such as on a USB stick) or sent remotely over the network or cloud. This is where software can play the role of sending, queuing, and tracking these print jobs. Cloud software such as the Ultimaker Digital Factory is enabling the next generation of FFF technology, delivering distributed manufacturing across multiple locations.

Watch this video to see how one manufacturer has created a "digital warehouse" by combining FFF 3D printers and software.

Want to learn more about how the 3D printing workflow could look for you?

Read our ‘How to design for FFF 3D printing’ white paper for valuable tips for getting started with an FFF printer, more detail about the role of support materials, and design for FFF insights from 3D printing experts.