Digital fabrication informs ceramics decorative process

Pioneer Young Kim blends his classical arts background with digital fabrication to create a ceramic project that incorporates 3D printing.

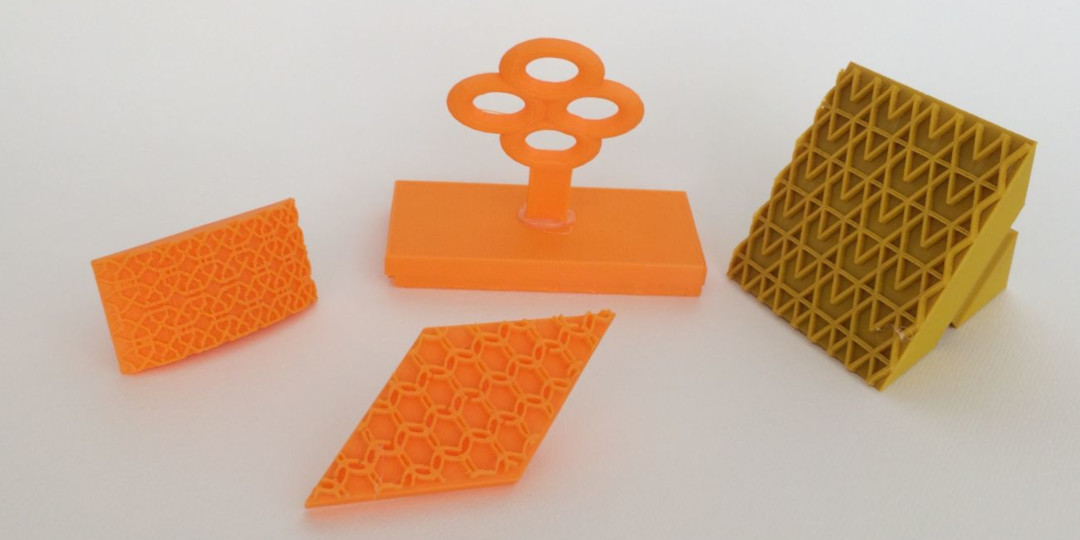

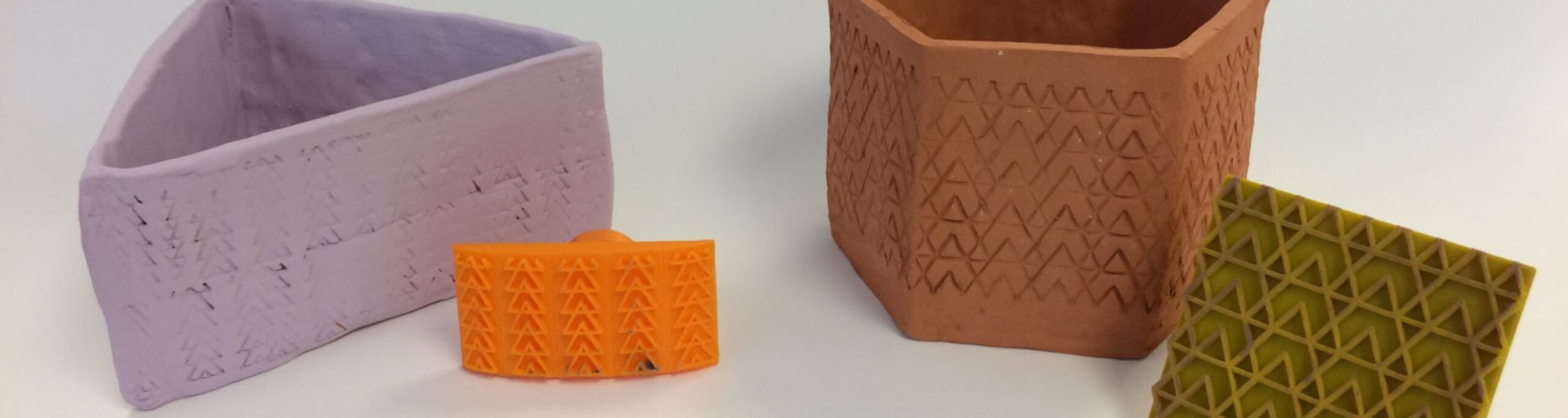

During the past school year at Hewitt School, a K-12 girls private school located in New York, I was given the chance to combine my two teaching backgrounds: technology and visual arts. The interdisciplinary curriculum was a natural transition for me to combine my prior arts education background, new digital fabrication techniques, and ceramics. The focus would be to merge technology and hands-on three dimensional design and fabrication. The Art Department’s middle school curriculum for 7th and 8th grade worked on a rotation of Studio Art, 3D Art, Digital Art, and a 8th grade spring semester intermediate level course. The intermediate level course was picked by the students to further explore a visual arts topic of their choice. I led the students through a two-part project incorporating 1) web-based tools, 3D modeling, 3D printing; 2) slab built geometric clay boxes, surface decoration, and glazing. I’d like to share some of the main procedures (see 3D Printed Pattern Stamp & Ceramic Box lesson) and reflections on the project.

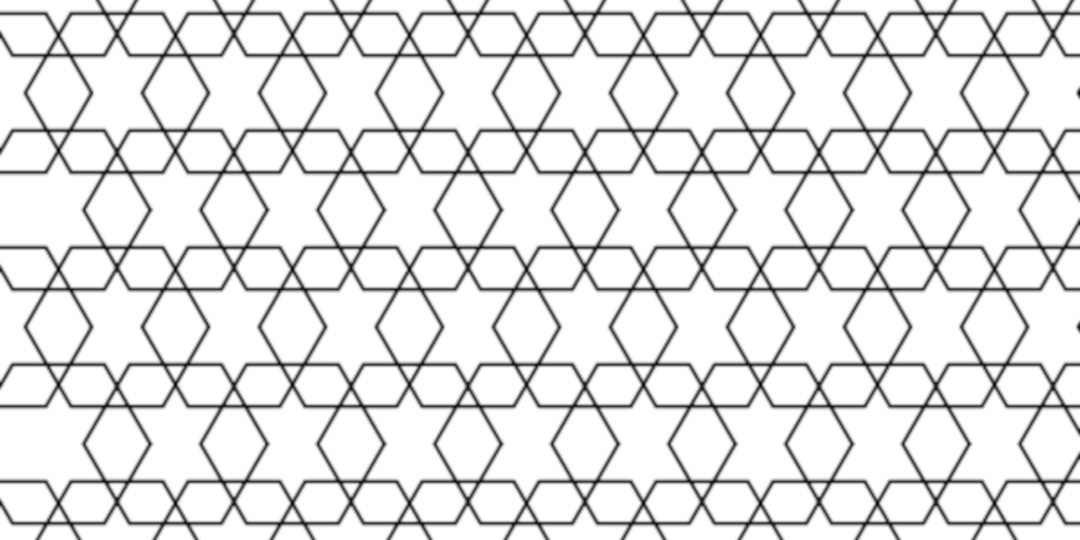

The middle school students are assigned a Chromebook for use in school and at home, so all the digital tools needed to be web-based. Tinkercad would be the main tool for designing the pattern stamp, but I needed other tools to create the pattern image and file convertor. The procedures for saving, retrieving, and converting the files needed to be specific for the Chrome OS because the “File Browser” is an infrequently used feature on the Chromebooks. There was some confusion on how and where files were saved, but the students were able to help each other out. The majority of the students were confident in creating 3D models of a stamp handle and body. The challenging part was modifying the imported SVG file, especially proportionally scaling down and raising the pattern object onto the surface of the stamp. A technical challenge I faced while 3D printing the stamps was losing the pattern lines on the stamps. We were able to resolve this issue by duplicating and shifting the pattern lines in the 3D model. Overall, all the students successfully created unique stamps to use with their clay boxes.

It has been quite a while since I’ve taught and fired ceramic projects, so I was nervous whether any of the projects would blow up. Having a tight timeline did not help much either. In order to make sure the students had a general idea of the slab building process, I organized videos for them to watch on YouTube and had them take notes in their sketchbooks. This helped when it came to my live demonstration because I was assured they had a sense of what I was talking about. Reinforcing the instruction in different ways really helped make the studio time as efficient as possible. As the students worked, they faced some difficulty with getting the pattern imprinted on the clay surface. My students were expecting a perfect impression result from the first attempt. This final decorative step proved to be the most significant learning experience for some of my students. Every other procedure was controlled and tested before I taught it to them, but never could I have planned the perfect lesson on how to finesse their manual dexterity and pressure to make an impression into clay. This moment helped me realize the learning gap that exists in today’s manicured learning experiences. Due to so many different constraints (ie. time, funding, material waste, performance expectation) students lack the chance to familiarize themselves with the material, its nuanced properties, and their physical application of force onto it. This coming school year a new makerspace is coming online which will give my team a dedicated space to expand the technology curriculum. With this in mind, our school projects will always be planned out so as to have learning successes, but we also need to plan for opportunities to learn processes and time to explore the materials.