Dr. Sara Walton is a lecturer in the department of chemical and biological engineering at the University of Maine. In this article, she shares some projects from students who have used 3D printing for their Senior Capstone projects to solve real-world problems.

Talk of adding a 3D printing/computer aided design software lab into the bioengineering curriculum at the University of Maine began in 2014, around the same time that I joined the faculty. The industrial advisory board had cited this as a key skill they thought students should learn - and I was assigned to figure out how to make this happen. At that point, I had no experience with either CAD or 3D printing, and only a few weeks head-start on the students to learn these skills before the semester began.

In the first year iteration, we had students designing microfluidic mixing devices which we printed in the New Media department on their 3D printer. Reviewing after the first year, I realized that the assignment wasn’t presenting enough challenge in CAD creation to really develop this skill set, and also that using machines in another department didn’t encourage the students to have much involvement with the process of 3D printing itself.

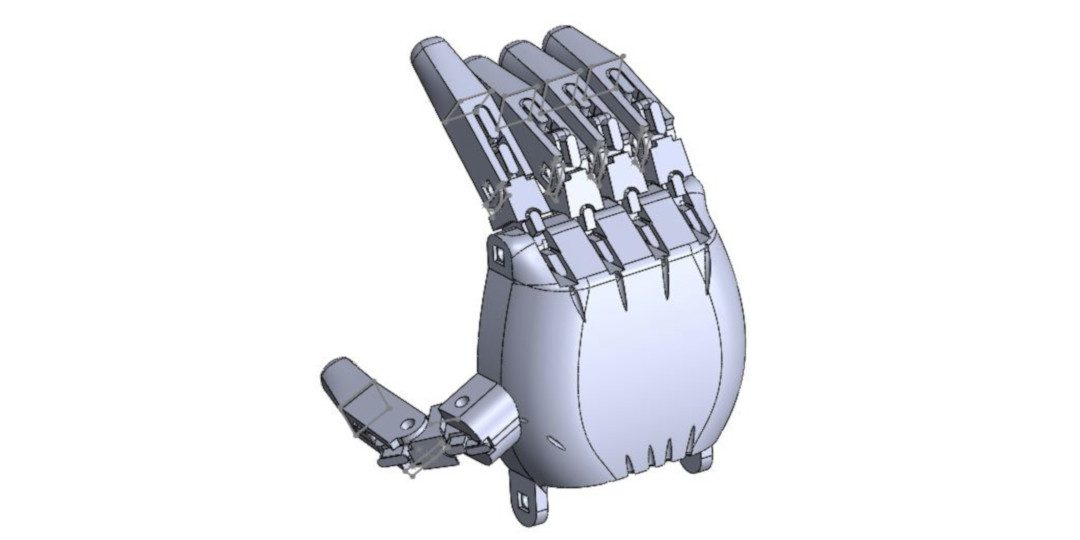

For the second year iteration, I got approval to purchase a 3D printer of our own---and spent weeks reading product reviews before finally settling on the Ultimaker 2. I changed the assignment to the creation of 3D printed prosthetic hands, inspired by the e-nable foundation. Students were allowed to take inspiration from the open source community, but in order to develop their CAD skills, they had to design all of the pieces themselves.

This is a SolidWorks assembly image from one of the student-created hands.

The complexity of this project was a greater challenge, and our students were now proficient enough in SolidWorks to make good use of the CAD software in their senior capstone projects.

Senior capstone project teams in the Bioengineering department are each assigned a problem from an industry sponsor, and the team builds a prototype device to demonstrate their solutions. The projects for the class of 2017 that involved 3D printed components included a pediatric breathing simulator, a soft robot, an ultrasonic mosquito larvae exterminator, a blood hemolysis detector, and a cell scratch assay device for wound healing studies.

Pediatric breathing simulator

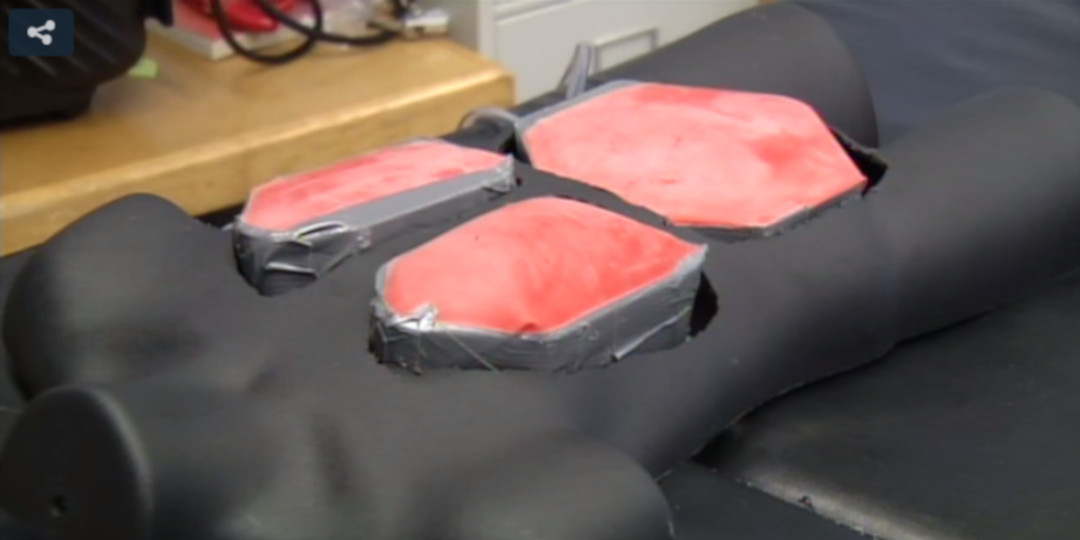

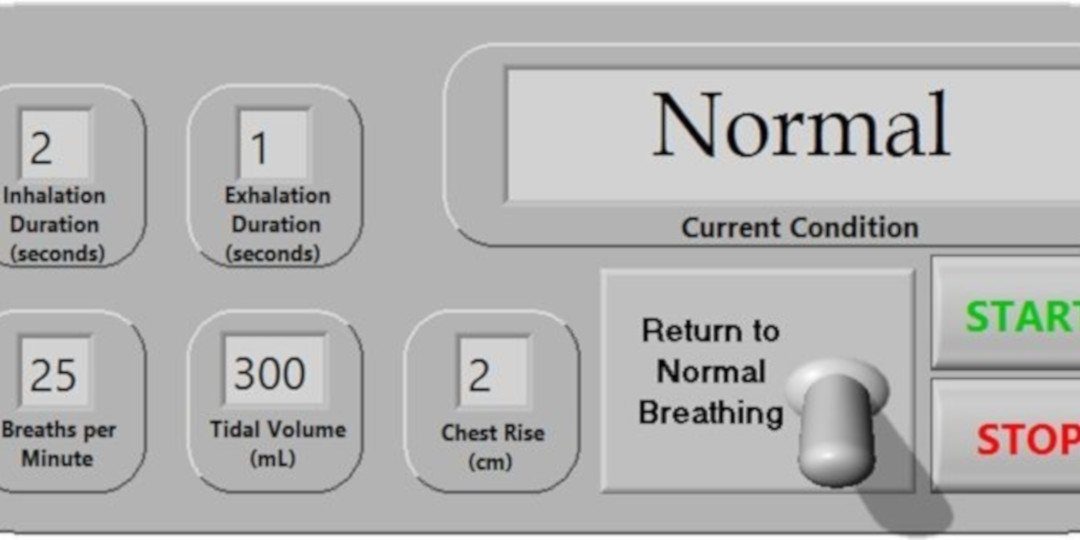

The pediatric breathing simulator is a medical manikin that can be used in training healthcare professionals to recognize normal or distressed breathing patterns in children. The lungs and diaphragm compartments within this model were 3D printed using the Ultimaker. An air compressor supplies air flow through series of pressure regulators, tubing and solenoid pinch valves. A LabView program is used to select the desired breathing mode (normal, seesaw, respiratory distress or collapsed lungs). A video of the device in operation can be seen here.

View of medical manikin, including lungs and diaphragm.

LabView program interface

Soft robot

Soft robots are a new class of machines bio-inspired by the compliance of living tissue, as exemplified by organisms such as octopi which can change their shape and size to meet the needs of their environment. The ability to deform upon contact has relatively recently been recognized as a highly useful feature for robots, particularly when it comes to the performance of delicate tasks such as handling fragile objects or interfacing with human tissues.

The foundation of soft robotics is the use of compliant materials which can be deformed through the introduction of air or water into an interior channel system. Silicone polymers (elastomers) are currently the material of choice for the creation of soft robotic actuators, as they are easily formable into the necessary geometries for actuation and can be tuned to give the correct stiffness for actuation.

SLIPS Technologies, Inc. (STI) is the sole manufacturer and distributor of a new class of self-cleaning silicone polymer. When combined with soft robotics, this system could permit new applications of soft robots in potentially high-fouling environments, including digestive tract surgery or marine applications, in which the robot “skins” remain clean throughout use. However, the slippery nature of these polymers make the use of standard soft robot designs difficult to use. The object of this project was to design a simple soft robot that would work with STI's slippery polymer.

The Larva Blaster 3000

The Eastern Equine Encephalitis Virus (EEEV) is an emerging human and veterinary health threat in northern New England and is primarily transmitted through mosquitoes (Culiseta melanura). Cs melanura mosquitoes are unique in that their larvae remain alive over the winter months, hidden in un-frozen water-filled pockets called crypts, located under the roots of trees. This survival strategy makes traditional methods of controlling mosquitoes, such as the application of pesticides or draining water bodies, more difficult. The objective of this project was to design and prototype a device for destroying mosquito larvae in the crypts, particularly during the colder winter months.

The device should not be harmful to the surrounding plants or animals. This device was created for the Lyme & Vector-Borne Disease Laboratory at the Maine Medical Research Institute. The Larva Blaster 3000 is an ultrasonic mosquito larvae reduction device created by the capstone students.The probe head and device casing were 3D printed.

The probe head houses the ultrasonic transducers and a water sensor.

Crypts where mosquito larvae might be found

A flexible cable attaches to the device housing, which contains an Arduino microcontroller, breadboard, battery, and three LED lights which illuminate if (1) the water sensor detects water, (2) the transducer is too close to an object for effective use, or (3) indicating the device itself is powered on.

Cell scratch device for wound repair research

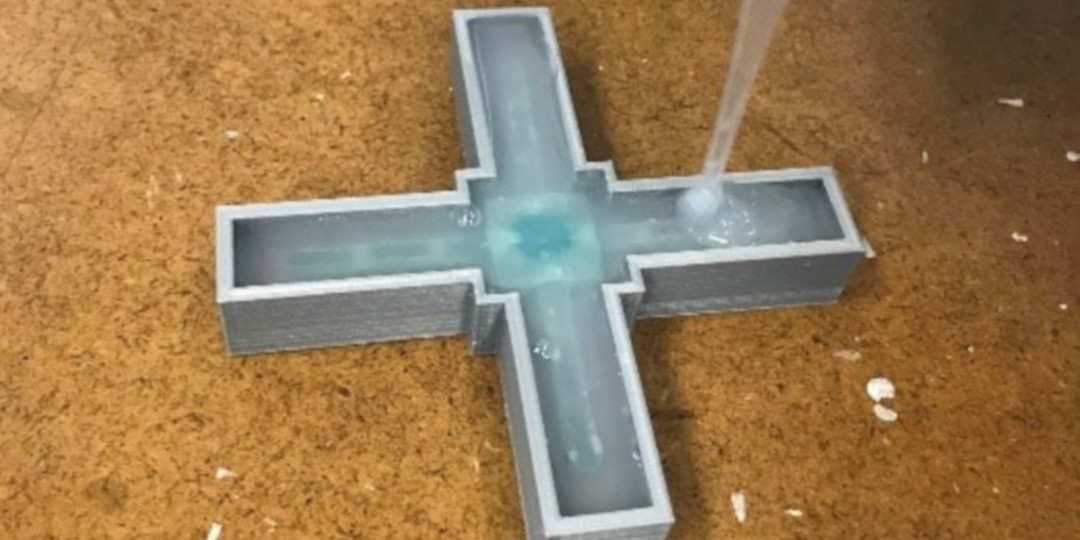

The Rieger group at Mount Desert Island Biological Laboratory studies wound repair mechanisms in zebrafish and human keratinocyte cell lines. They have discovered that low concentrations of the small reactive oxygen species hydrogen peroxide (H2O2) stimulate keratinocyte migration whereas high levels are inhibitory. To further assess H2O2-dependent migration mechanisms in human keratinocytes, they need to perform scratch assays.

A typical scratch assay is performed by letting the cells grow to a confluent state in a 24 or 48-well glass bottom multiwell plate, and making a 100-200µm scratch in three separate regions of each well. Scratch closure is thereafter observed over time. They have performed scratching so far with a pipette tip, which requires that the scratch width must be measured immediately after scratching to be able to quantify the closure distance. This requires that the initial scratches be imaged in a light microscope, which can be a substantial burden. In order to avoid this extra step, a device must be designed that can make such precise scratches that no initial imaging or measuring has to be performed.

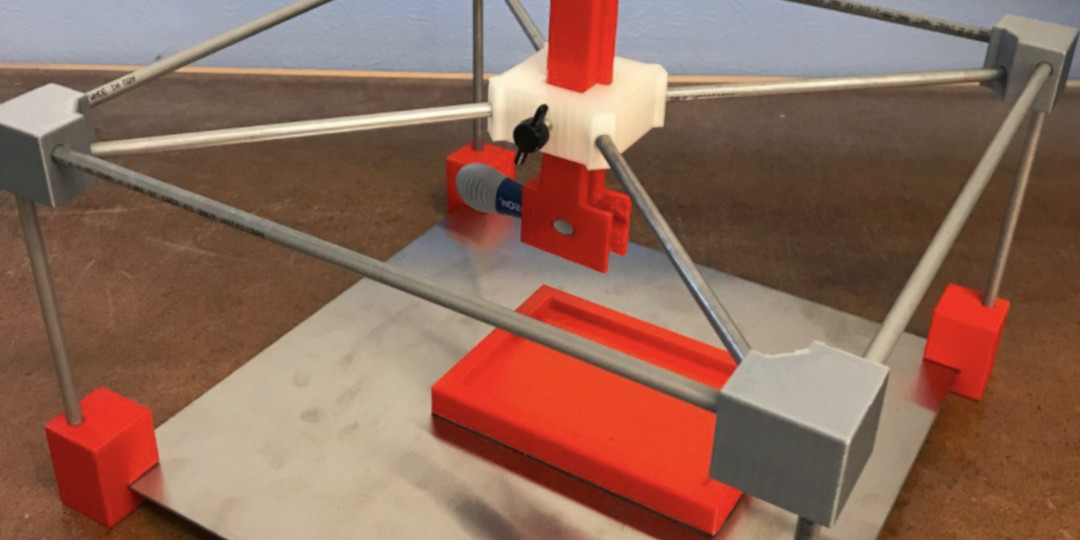

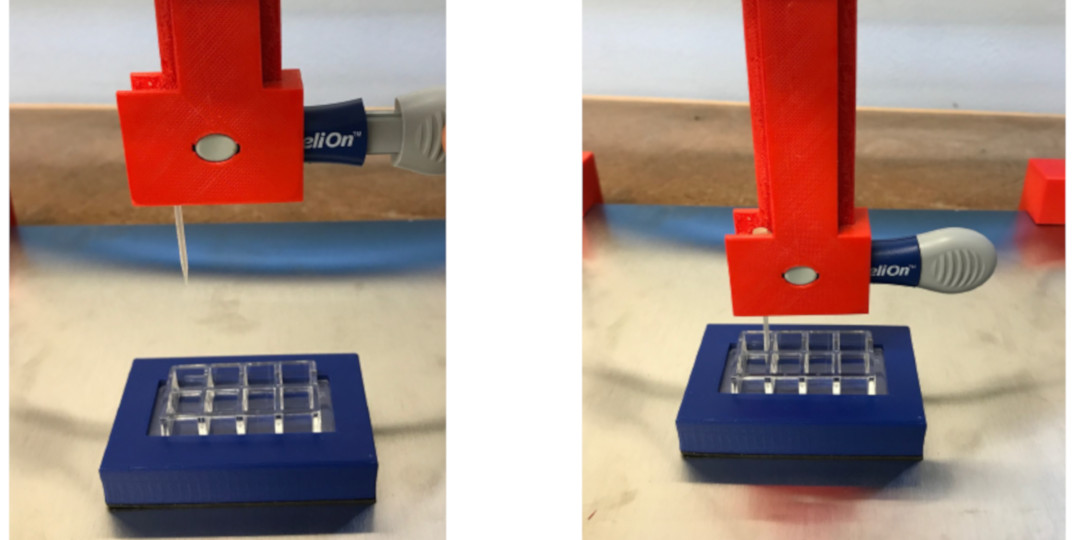

This is part of the prototype cell scratcher device. The corner pieces, well-plate holder, and central assembly are all 3D printed.

Raised and lowered views of the cell scratching device.

Hemolysis detector

Hemoglobin is essential for the transport of oxygen in the bloodstream. Under normal conditions, it is contained within erythrocytes (red blood cells). Under pathological states, hemoglobin may be released into the bloodstream due to erythrocyte cell lysis. It is then broken down into hemin and heme, which is toxic to cells.

Diseases in which free heme plays a role in detrimental health effects include sepsis, thrombosis, sickle cell disease, renal failure and liver failure. The objective of this project was to develop a method for detecting high levels of free hemoglobin in blood samples in a hand-held testing device that is relatively cheap and easy to use. The client for this project was Instrumentation Laboratories of Bedford, MA.

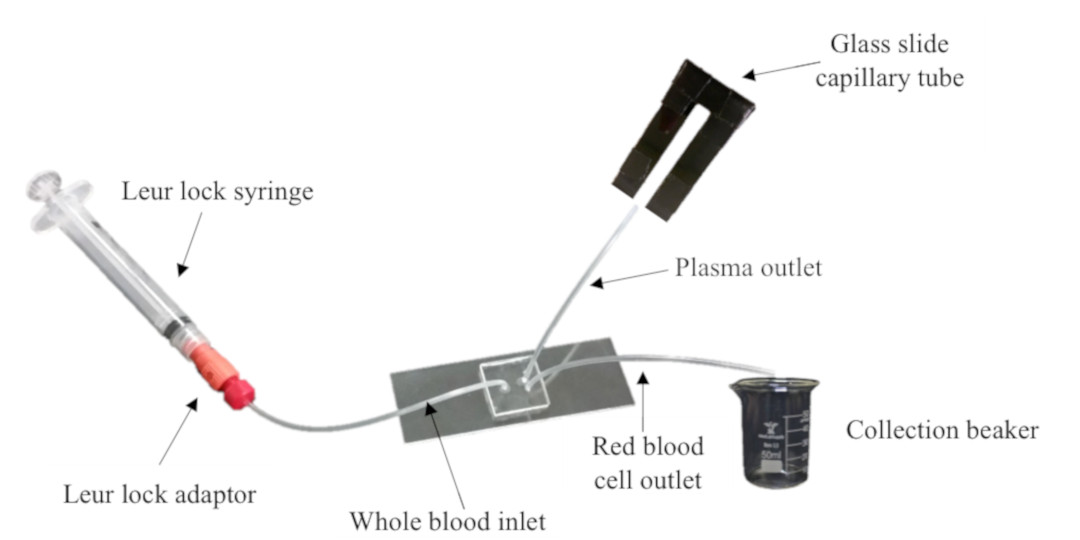

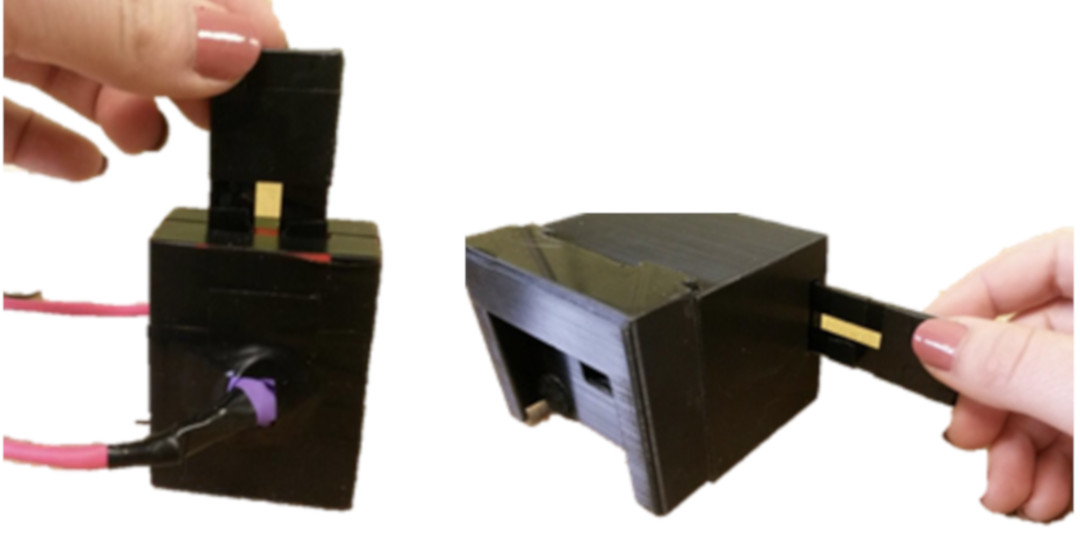

The capstone project device consists of a blood plasma separator and an optical detector. The plasma separator uses a microfluidic system to isolate plasma from red blood cells. Free hemoglobin remains in the plasma, permitting efficient detection using a photoresistor and LED to determine the concentration of free hemoglobin. A second option for optical analysis using a mobile phone camera was also provided.

Schematic of initial blood separation process using the microfluidic device

The glass slide capillary tube can be inserted into either analysis device (left) optical analysis chamber, or (right/bottom) cell phone filter attachment.