When thinking of 3D printing in the food industry, often the first thing that comes to mind is printing directly with chocolate or other edible substances. But an interesting alternative that is becoming more popular is using 3D printed shapes as a master to create food-safe molds.

We'd like to show you an eclectic mix of companies that are using 3D printers for this purpose. They are not just using these molds to expand the variety of shapes they can offer their products in, but are also exploring small-batch production runs of custom designs for clients. Before the spread of desktop 3D printing, this could not be cost-effective, as making an aluminum mold was expensive and would only become profitable with large production runs. But now brands, advertising agencies, and events are making use of this new trend to get personalized goodies to their audiences.

3D printed lollipop shapes

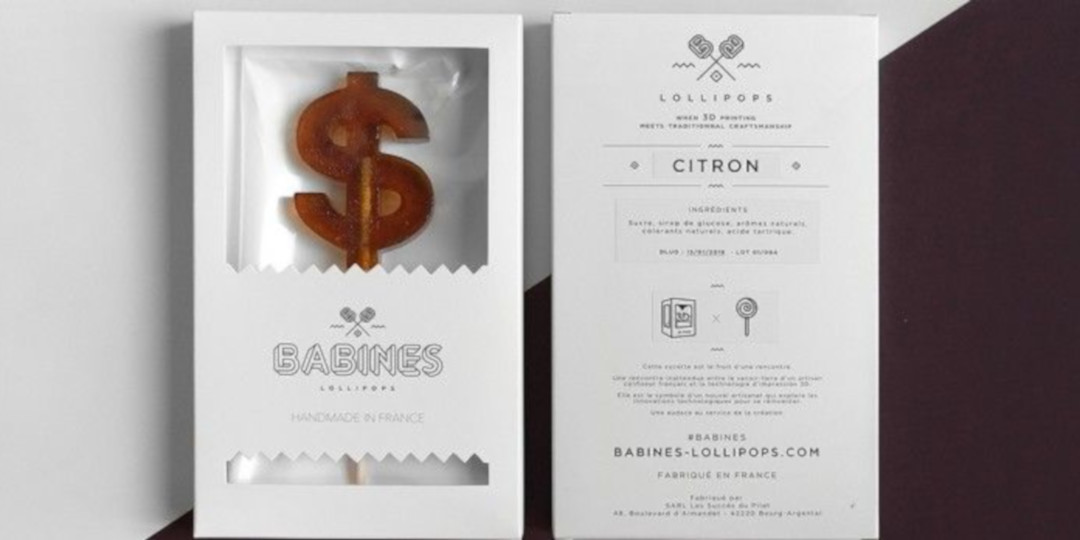

The Babines Lollipops shop in Paris creates modern lollipops in trendy pop culture shapes that no traditional confectionary would think of. The lollipops are drawn, modeled and then 3D printed on an Ultimaker at the company's lab in Paris. The Facebook 'Like' icon, video game controllers, dollar signs, and anything else that's relevant today can become a lollipop. Using food-safe silicon a mold of the 3D print is created, which is then sent to an artisan confectioner in the Loire. This classically trained craftsman creates the sugar mix for each flavor lollipop and pours them by hand into the silicon molds.

Babines was founded by Victor Barnouin, who had previously done work for several French lifestyle brands. He noticed that all of them were constantly on the lookout for new high-end, promotional goodies that could be used to make them stand out from the competition. Mixed with the resurgence of artisanal trades during the recent recession, Victor was inspired to create this concept of traditionally made, but custom-designed, lollipops.

It seems to be a good time, the millennials and Facebook and Instagram, everyone’s taking selfies — so why not lick your own face?

3D scanned custom face candies

London-based Candy Mechanics takes a similar, but even more customized approach to their confectionary production. Instead of designing new shapes themselves they use a 3D scanner to create a model of each customer's head. Their Ultimaker creates 3D prints of these heads, which are used as masters for vacuum-formed plastic molds. The molds are filled with chocolate and topped with sprinkles ranging from chocolate crumb to freeze-dried raspberry. It might seem a bit vain, but the chocolates are becoming all the rage as party favors at events like weddings, birthdays and bar-mitzvahs.

Founders Sam Part and Ben Redford teamed up with professional chocolatier Will Leigh to get their startup off the ground. In a record six-week period, they went from opening the boxes filled with brand new machines for the first time, to setting up a fully functional pop-up store inside British retail giant Selfridges. “It seems to be a good time,” Sam says, “The millennials and Facebook and Instagram, everyone’s taking selfies — so why not lick your own face?”

3D printed icepop molds

Of course, when we're talking about using 3D printing to create custom food molds we can't forget to mention MELT. We covered MELT's story two years ago when they had just started operations in Amsterdam, a fun idea thought of in the back of a cafe but brought to fruition to become an actual business.

Eva Snellen and Leonie Smelt were inspired to start MELT when they heard of the 50th anniversary of the most iconic icepop design in the Netherlands, the 'raketje' (rocket). They design their own models, 3D print the shapes on their Ultimaker and use that print as a master in their home-made vacuum former to create the various molds.

Now they have internationally known clients such as Tony Chocolonely, TEDx, national museums and even Ultimaker! When we celebrated our move to a new office last year, we asked MELT to supply us with these special Ultibot shaped icepops.

Three companies that are using 3D printing to create food molds, to approach a market they could not before. It's great to see the difference that 3D printing is making, enabling these entrepreneurs to escape the demands of industrial-sized production runs and instead create these small custom batches.