After reading about 3D printing and giving it a try for himself it changed his whole world. The entire process of building and designing his own RC-car became so much faster and easier. According to James, “It sped up the building process significantly and opened so many more exciting possibilities. I think I can honestly say I’d be lost without my Ultimaker in my life."

The world's fastest 3D printed R/C car

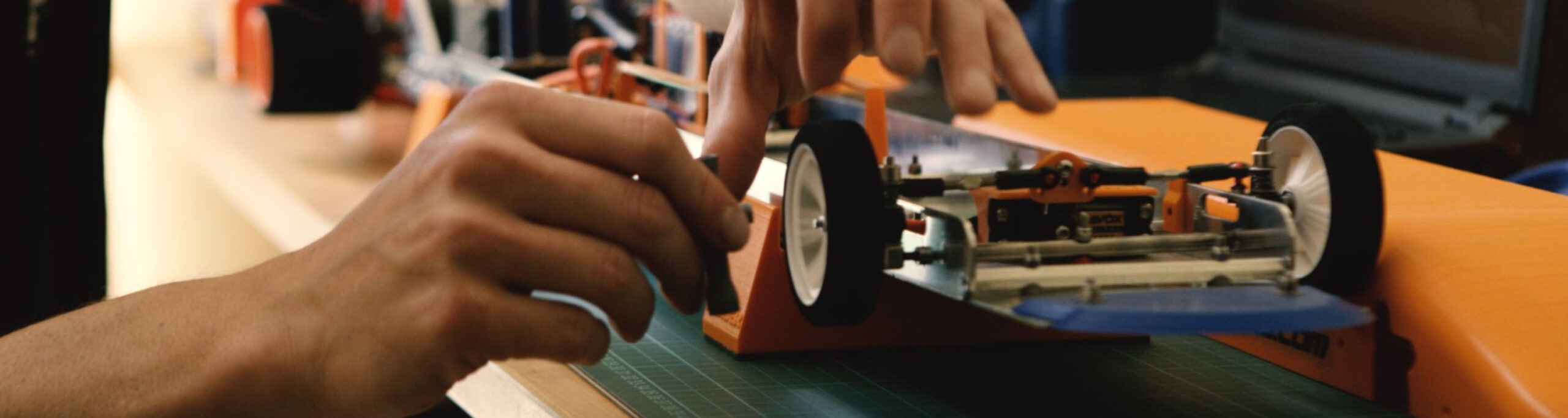

James Beswick always had a bit of a thing for radio-controlled cars – especially high-speed drag racing. He’s been building them for a few years now but decided to take things to the next level. To do that he realized he was going to have to think outside the pre-built box and build his own!

"For me the only hard part of the process is the waiting. I don’t always get the parts perfect first time but with the nature of 3D printing it’s so simple to go back to the design and make slight changes, then try again. The process is as simple as: Imagine, Design, Print, Enjoy!”

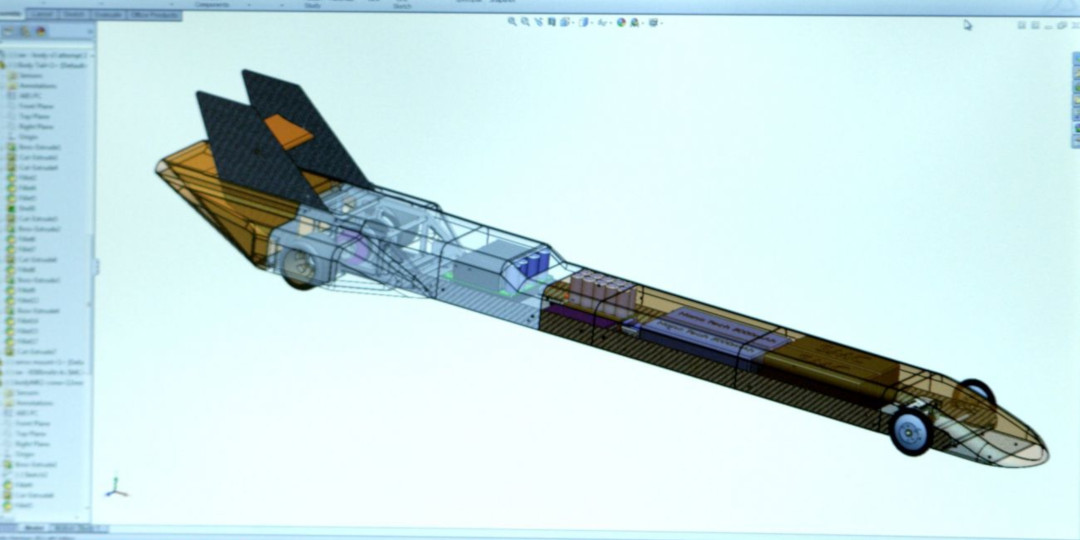

With bold new ideas to try James wanted a machine he could use to create both the 4-foot-long body-shell and the high precision internal parts required. The Ultimaker 2 Extended got his attention thanks to its taller build volume, which was exactly what he needed. To beat the competition James would need to come up with a unique body design that was strong and had minimal air resistance. The build volume of the Extended allowed for larger, more streamlined parts to be built.

The current R/C world record has very recently been set at 202 miles per hour and I won’t be stopping with the development of my project until I can go faster.

The open filament system was another big plus, as it allowed him to experiment with various materials to uncover the best characteristics for different parts. After a short spell of testing James settled on a flexible filament for shock absorption, but a PLA/PHA filament – PLA made less brittle by being blended with a more flexible PHA polymer – for the body due to its strength and lack of warping.

Not just the body-shell was printed on the Extended. The rear wing, servo holders, controller mounts, battery and cable clamps, even shock absorbers for the electronics were also 3D printed. And thanks to the fast process of 3D printing and its low cost, James can continue his streak of improvements. So far the design of the body has proven to be extremely stable, but as the speeds increase subtle changes will be needed in the aerodynamics to make sure the car stays firmly on the ground at high speed. "I’ve learnt through testing that stones at high speed versus PLA are a deadly mix, so in the next version of the body I’ll be printing I’ll be addressing a few weak spots,” he adds.

“The current R/C world record has very recently been set at 202 miles per hour and I won’t be stopping with the development of my project until I can go faster.” James told us.

Well, then I guess we’ll see him in the Guinness Book Of Records next – good luck!