-

3D printers

Back

S series 3D printers

Unlimited application potential.

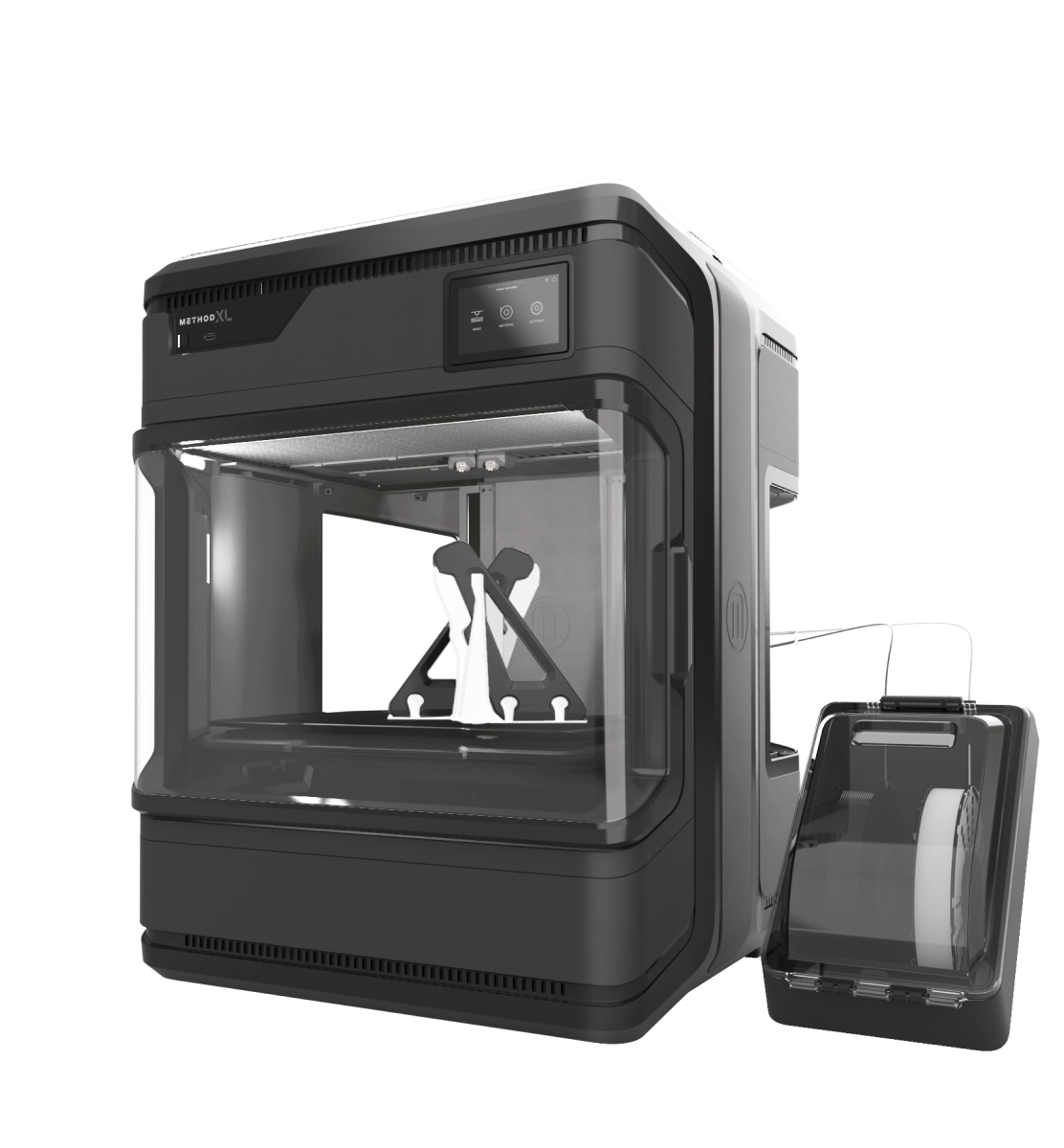

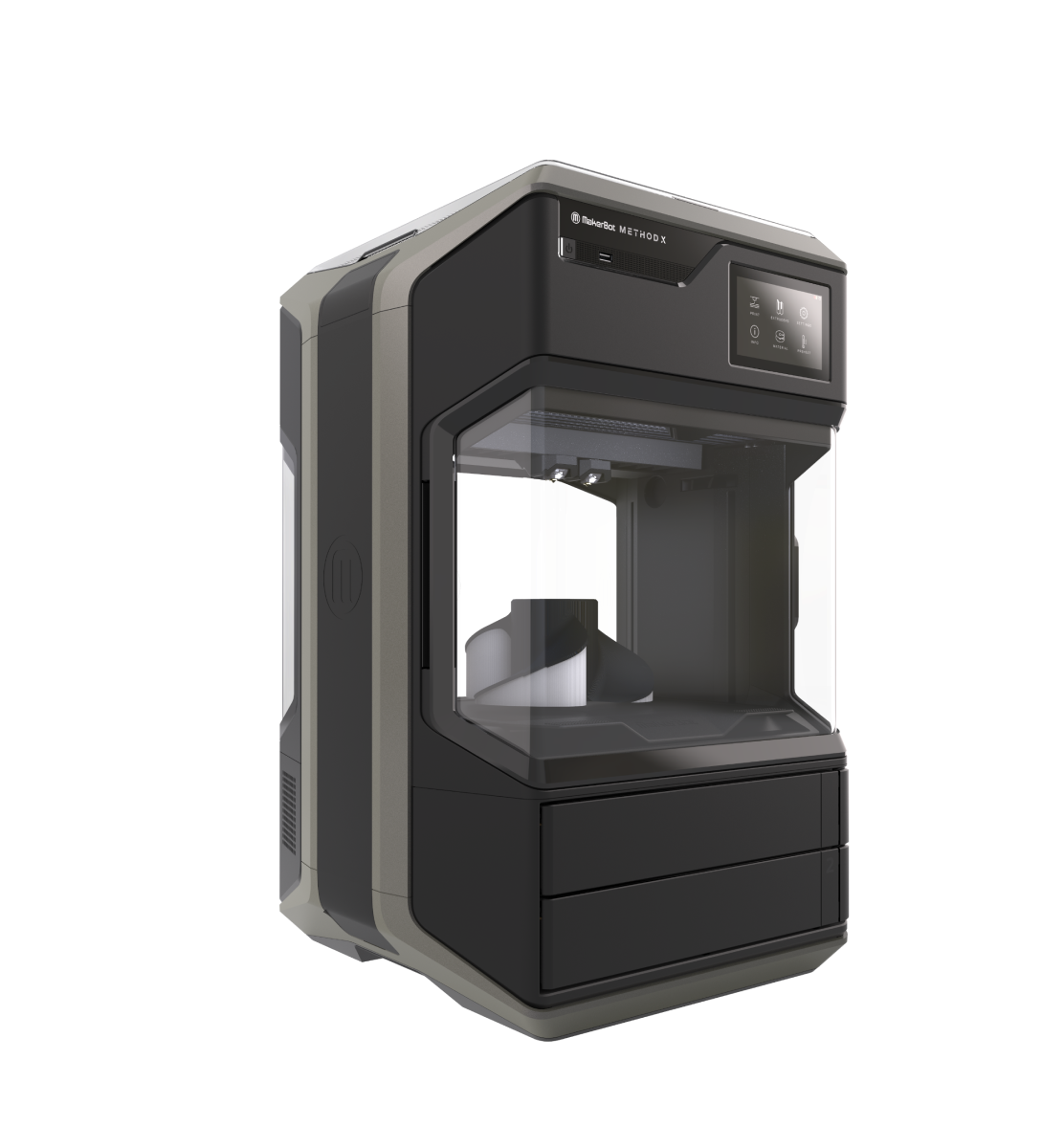

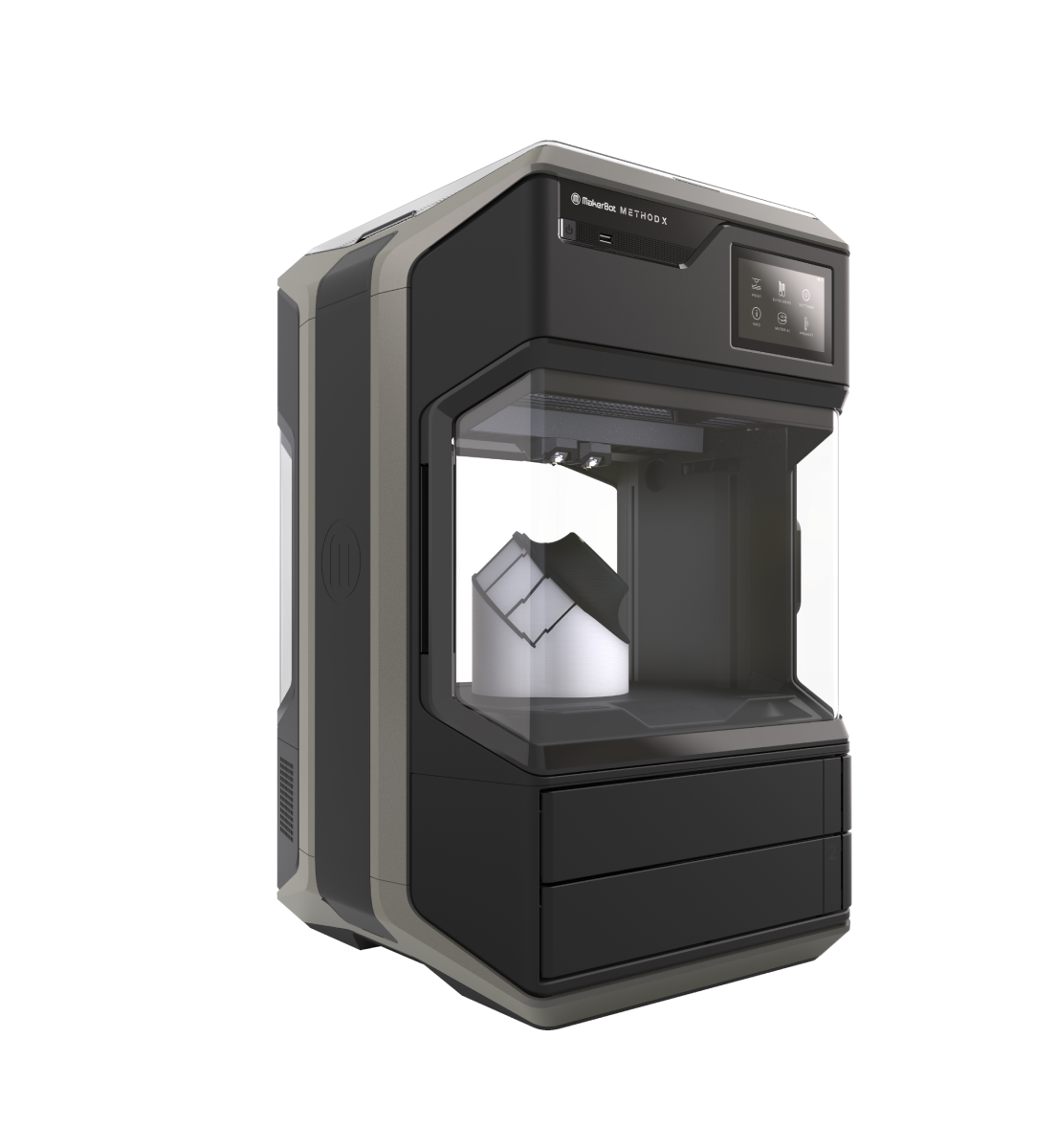

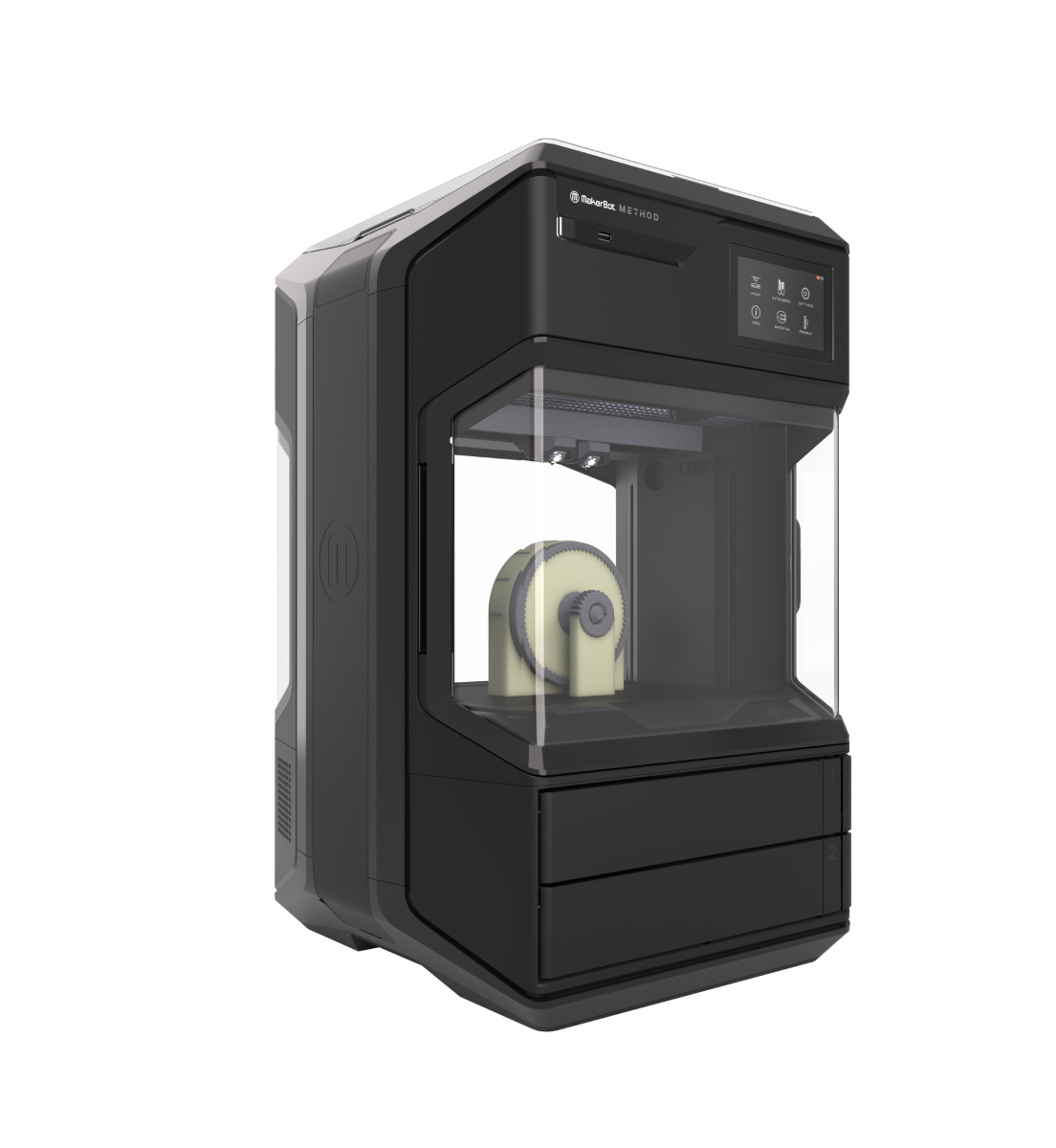

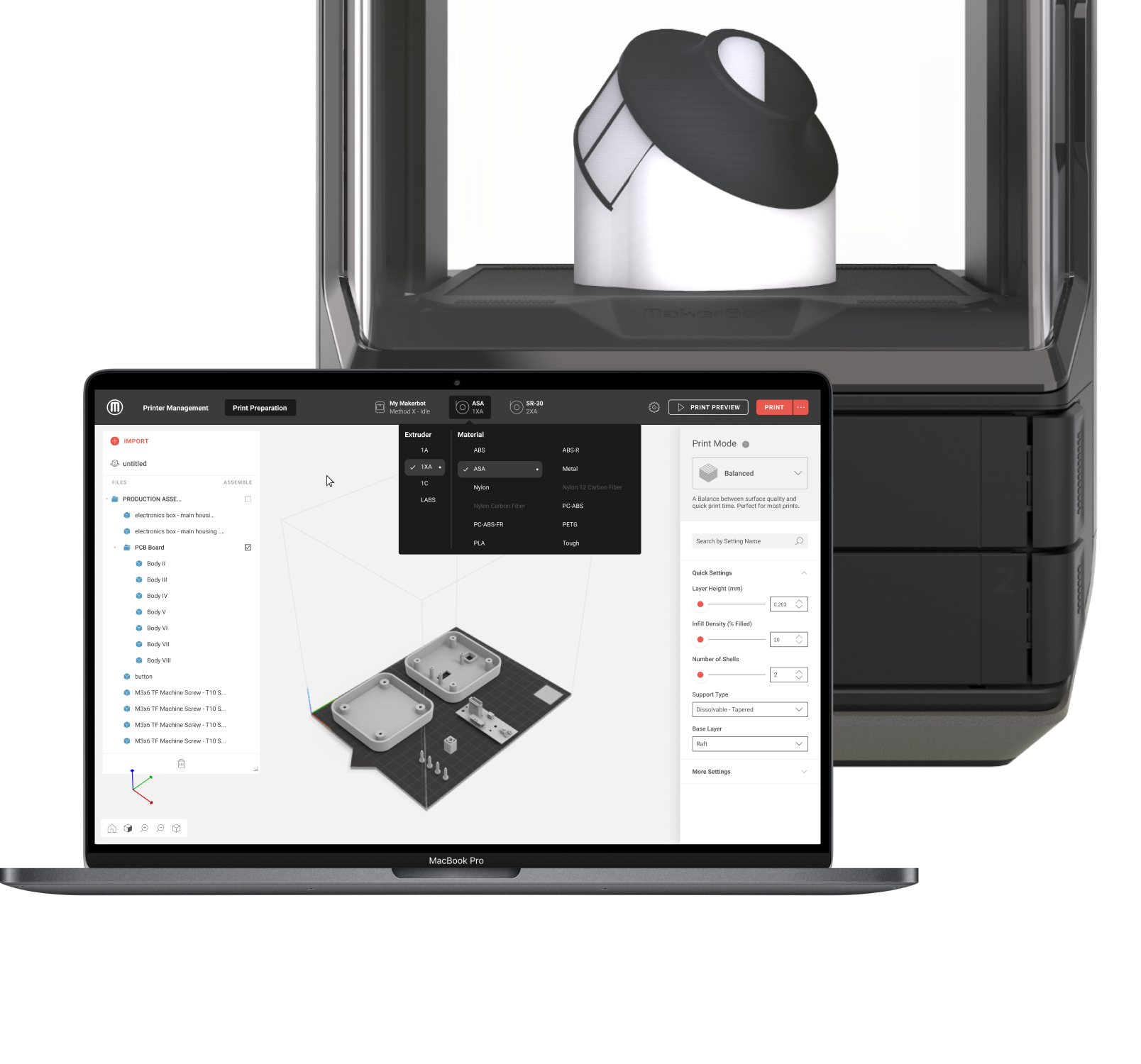

Method series 3D printers

Specialized for engineering applications.

-

Materials

Back

Factor series materials

High-performance and certified materials

S series materials

Over 280 materials to choose from.

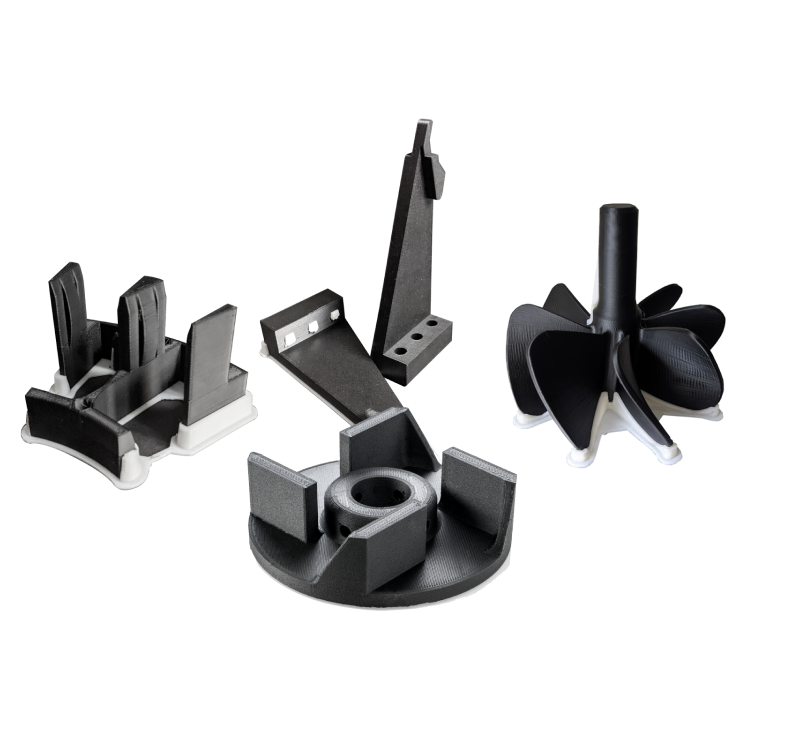

Method series materials

From polymers to composites to metals.

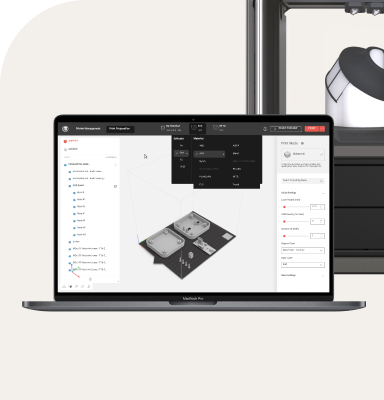

- Software

-

Applications

Back

Automotive

Optimize production processes

Defense

Keeping defense assets operational

Education

A 3D Printer Platform Made for Education

Product development

Take your designs to the next level

- Learn

-

Contact us

Back

Support

Explore our support content

Contact sales

Pricing or financing options

Contact us

Press and general inquiries

Open a support ticket

Contact our support team directly